SUPERFICIE

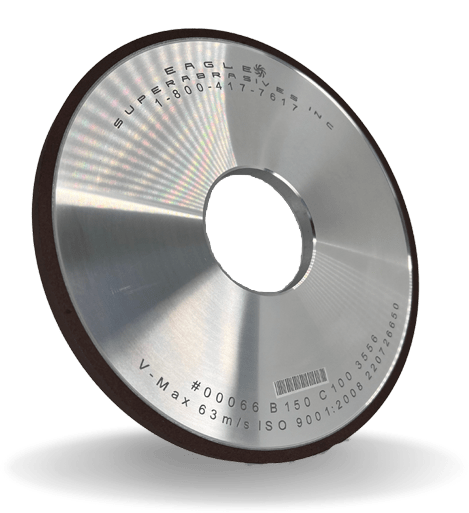

Surface Grinding Wheels

Surface grinding wheels are used to produce smooth finishes on flat surfaces. Surface grinding is one of the most common grinding techniques. The process typically includes a grinding wheel that contains abrasive particles (CBN or diamond) that grinds the surface of the workpiece, resulting in the face being flat or smooth.

Our surface grinding wheels come in a variety of abrasive grains and can be manufactured on six different core materials as well as multiple bonds. The bond selection depends on the material being ground and the desired stock removal rate along with other factors such as whether coolant is used and the machine type.

Speak to one of our engineers to get a wheel designed for your specific application.

Eagle’s Benefits

A surface grinding wheel from Eagle Superabrasives is a universal choice when working with difficult to grind materials that need rapid stock removal and precise tolerance.

Worried that a stock wheel won’t cut it for your application? No worries! We manufacture custom wheels daily, and some of these wheels can ship in as little as seven days.

Surface Grinding Styles

As with any workplace and the operation involved, different grinding techniques are needed to achieve optimal results.

A surface grinding wheel can be used in two different ways for grinding.

Horizontal surface grinding – This style grinds by placing the edge of the wheel so that it is in contact with the workpiece. Horizontal grinders are typically used for high-precision work on simple flat surfaces, tapers, or angled surfaces.

Vertical surface grinding – The face of the grinding wheel (segment, cylinder, or cup) does the grinding. The workpiece typically sits on a rotary table allowing for an even grinding finish.

UN LÍDER DE LA INDUSTRIA

DÉCADAS DE EXPERIENCIA

¿POR QUÉ COMPRAR CON NOSOTROS?

CONFÍE EN LOS EXPERTOS

Cuando esté listo para probar lo mejor, confíe en los expertos de Eagle Superabrasives . Ofrecemos soporte y servicio al cliente incomparables.

Con un amplio inventario de más de 6000 ruedas de diamante, CBN y CDX en existencia en nuestra ubicación de Carolina del Norte, podemos enviar el 90 % de los pedidos el mismo día. Los pedidos personalizados se pueden enviar en tan solo siete días.

Nuestro experimentado personal está dedicado a proporcionar a nuestros clientes productos de alta calidad y un excelente servicio. Ofrecemos soporte técnico y asesoramiento para ayudarle en el camino.

contáctenos para una cotización gratis

o llámenos al 33 31255419 – 33 36315374