It’s no secret that diamond grinding wheels offer multiple benefits from high material removal rates to minimal thermal damage. Proper grinding wheel maintenance plays a key role in making sure that your wheel delivers consistent results. If you landed here, you may be asking yourself, “How can I make my diamond grinding wheel perform better?”. Check out these four steps to improve your diamond wheel performance, achieve better results, and extend the life of your grinding wheel.

1) Establish what grinding wheel success means to you.

The first step in improving wheel performance is to identify how you measure success. You can do this by asking yourself a few questions such as:

● Do I want to extend the life of my diamond wheel?

● Am I looking for my grinding wheel to hold its edge better?

● Do I need higher stock removal rates and the ability to finish more parts in the same amount of time?

● Is a mirror-like surface finish on my final product my top priority?

2) Consider the surface…

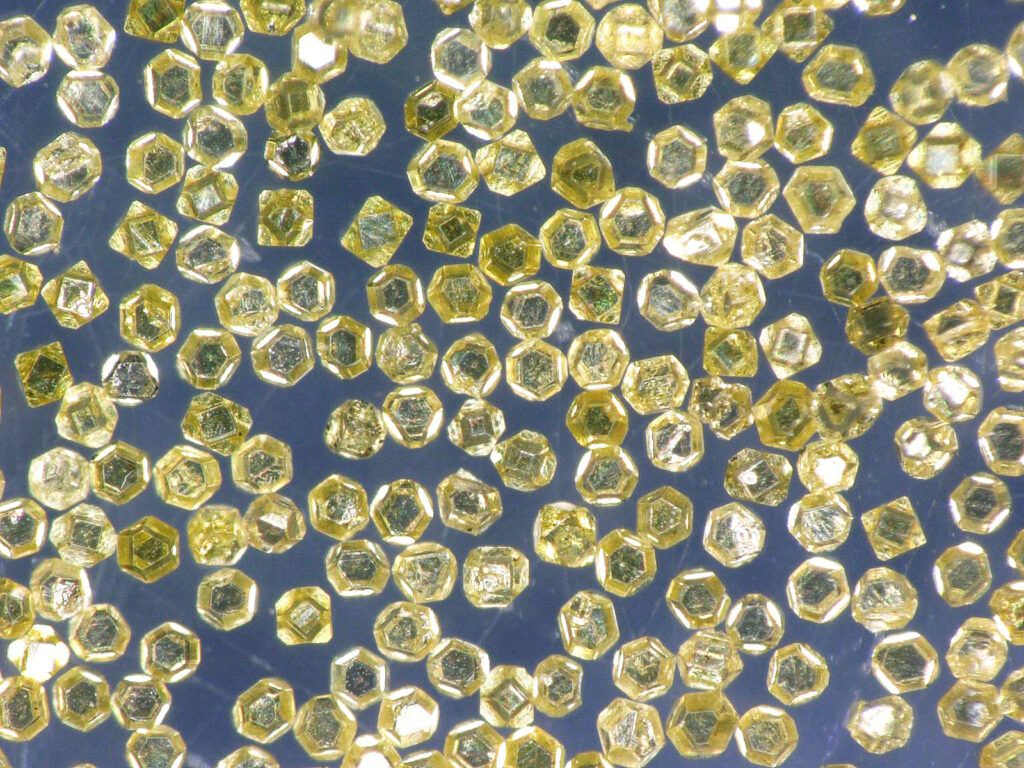

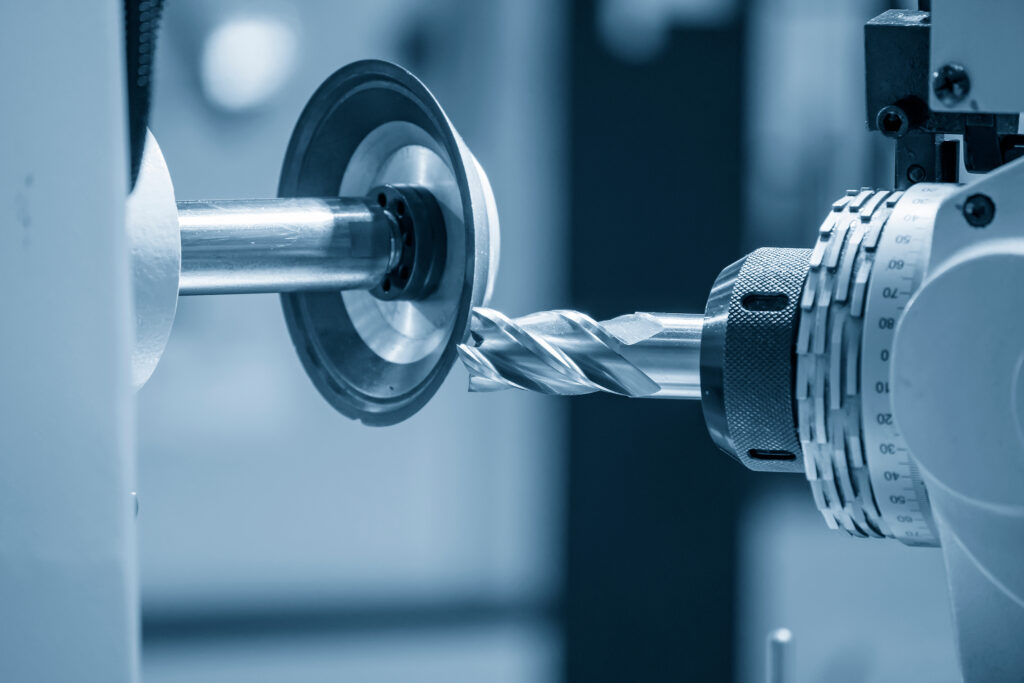

Diamond may be the hardest, naturally occurring material, but it does have its limitations. Diamond grinding wheels can be used on many materials such as quartz, alloys, carbide, and glass. Applications may also include HVOF, composites, PCD/PCN, and other non-ferrous materials.

In addition to the above surfaces, diamond is not well suited for steel or iron because of the intense heat reaction created when carbon and iron collide at high speeds. The grit of a diamond wheel will quickly erode if subjected to ferrous materials. Overall, diamonds are great for most anything else. They effectively cut through ceramics, sharpen carbide, and polish granite. If you’re looking to apply a grinding wheel to specialty materials, diamond wheels are the go-to option.

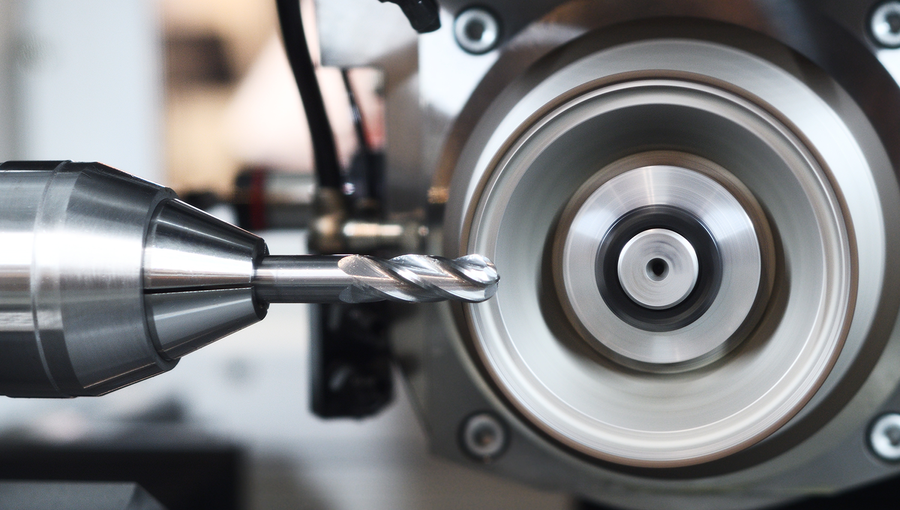

3) Wheel check, please!

After purchasing a new diamond wheel, you’ll be excited to put it to work; but remember to check your wheel (before you wreck your wheel)! Diamond wheels must be inspected to ensure there are no damaged areas or cracks. Make sure to test for run out before use, and confirm that the flanges, back plates, and spindles are clean. It is also a good idea to verify the cutting edge is open and sharp. A quick check of your grinding wheel may save you a lot of time (and money) in the long run.

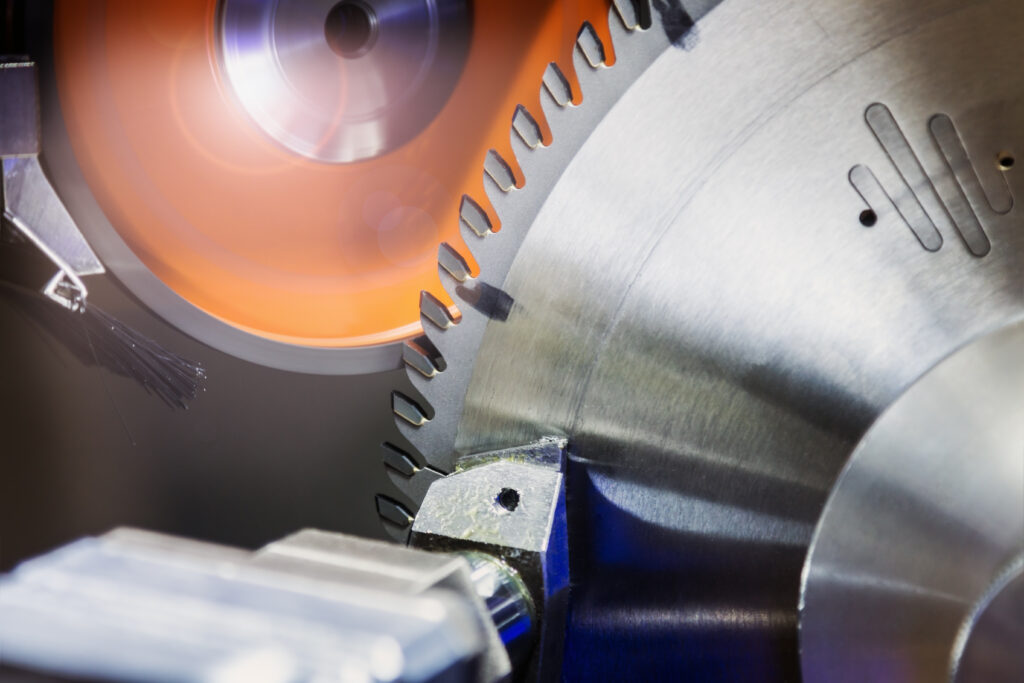

4) Diamond Wheel Operating Conditions

A diamond wheel is designed for straight cuts with pressure evenly applied. During use, remember to avoid excessive pressure, jamming and twisting. Making these mistakes could cause cracks and section loss. To get the longest life out of your diamond wheel and the highest material removal rates, remember to operate your wheel under the right conditions. These four conditions include wheel speed, work speed, feed rate, and use of grinding fluids.

Wheel Speed

Wheel speed is measured by surface feet per minute (SFM) and calculated by using the diameter of the wheel and spindle speed of your machine. This can be measured in meters/second (m/s) or revolution per minute (RPM). Useful guidelines can be found on our wheel speed chart. However, there are other factors that can cause you to have to run a little faster or slower, such as whether or not you are using coolant.

The SFPM can cause a wheel to act softer or harder than usual, depending on how low or high it is. If the wheel seems to be losing its edge too quickly, you may need to speed up the wheel. If it seems it is not cutting at all, you may need to slow it down.These variables should be taken into consideration when determining the life and effectiveness of the wheel.

Eagle Superabrasives offers a phone app that can assist you in determining what SFPM you are running. You can enter the diameter of your wheel (in millimeters or inches) and the spindle speed you are running at (RPMs or m/s) to calculate your SFPM.

Work Speed

Table traverse speed (crossfeed) is mainly controlled by the amount of down feed (depth) of cut. Because these can vary greatly depending on the operation, machine, and conditions, specific work speed rates can be hard to define. The best speed is usually found through testing and can be pinpointed when there is no loss of speed or excessive wear on the wheel.

Feed Rate

Shortening the life of your diamond wheel is something you want to avoid. To ensure this doesn’t happen, be careful to not cut too deep. This can result in cracked wheels, burns, and chips. Depending on the application, many errors can occur as a result of this mistake.

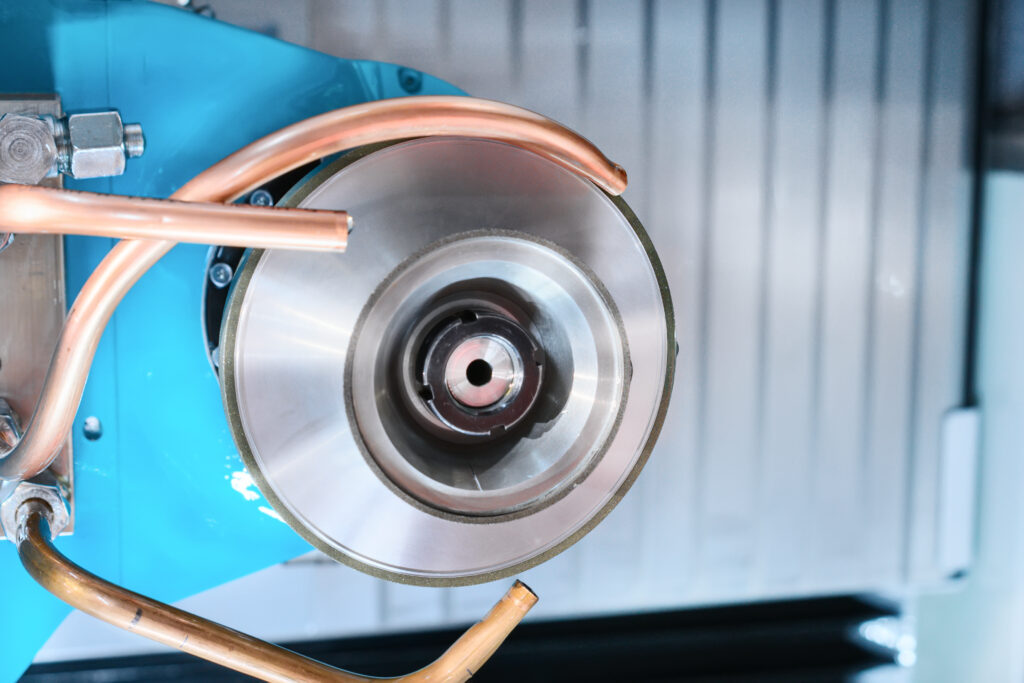

Cutting Fluids

Whenever possible, use grinding fluids with your diamond wheels. They reduce the grinding heat while extending the life of the wheel. Applying coolant the right way is also important. When applying the coolant, allow the centrifugal force of the wheel to distribute it in a constant stream to the area of grinding contact. If dry grinding is your only option (ex: cutter grinding), a resin-bonded wheel should be used. Most wheel manufacturers offer a wide range of resin-bonded wheels that have been specially designed for dry grinding cemented carbide tools. These grinding wheels are very effective and can maintain productivity without the use of any coolant.

After reviewing the above information, we hope you found some useful tips to increase your diamond wheel performance.

At Eagle, we believe in making small changes to deliver exactly what you want from your diamond grinding wheel. Our application engineers will guide you through the entire process; from understanding your options to product support after your purchase. When you’re ready to get started, our engineers are standing by and can be reached by phone or email to answer your questions.

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel