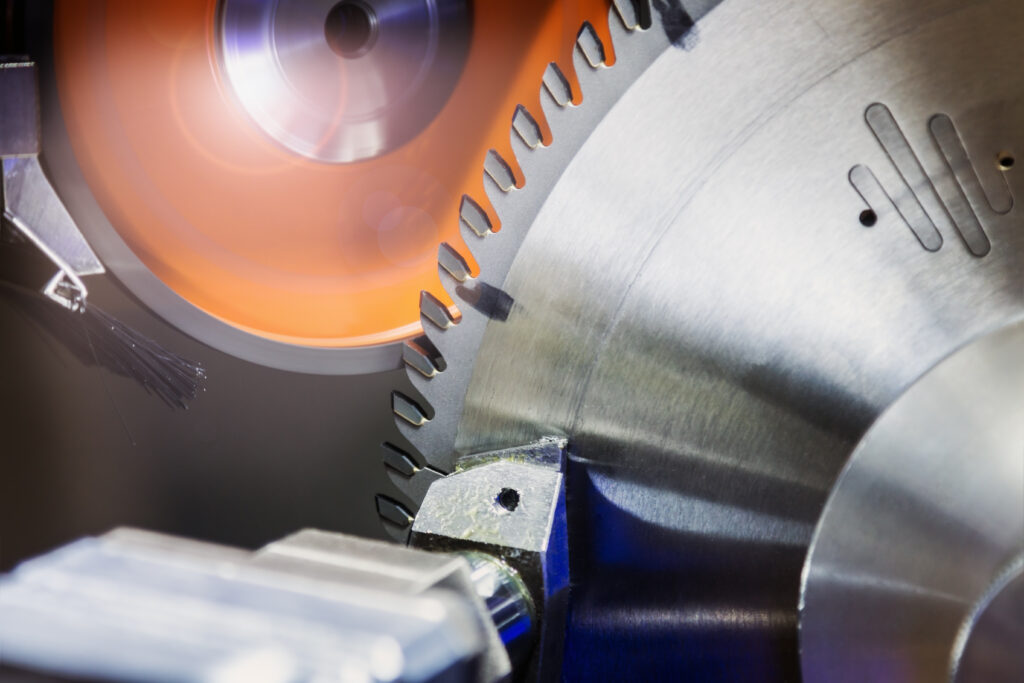

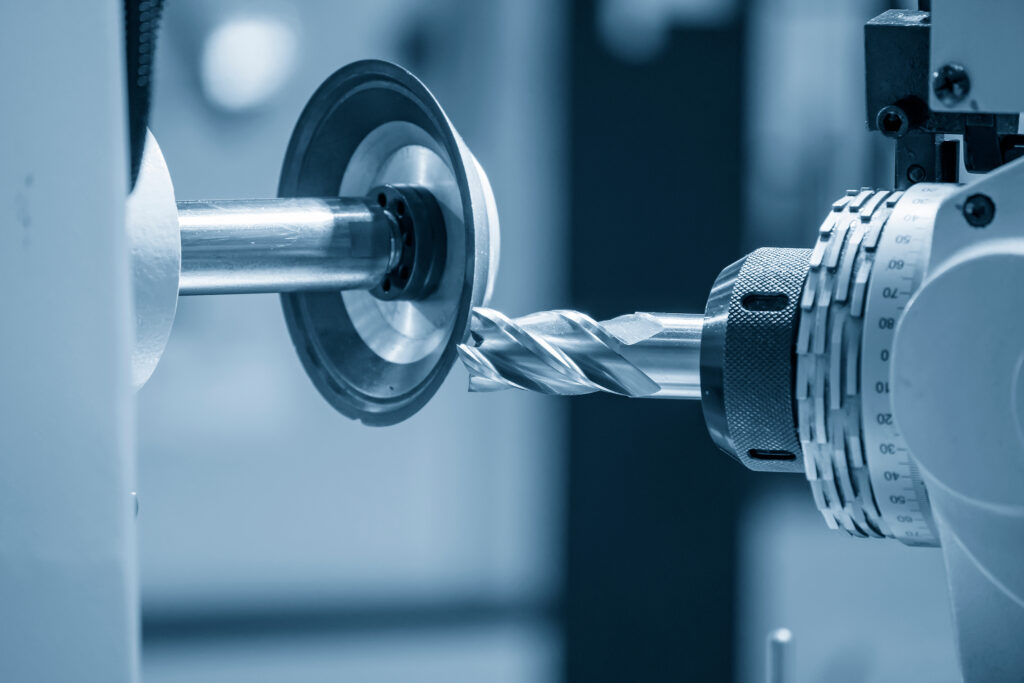

When selecting the components of a grinding wheel one must carefully consider the many abrasive options available. Depending on your grinding operation, material specifications, and desired removal rates you will need to select specific abrasives. There are a wide range of materials to consider, each with their own cutting performance, life span and expense. Let’s take a look at two of the top contenders offered on the market to compare and contrast the industry’s classic, general purpose aluminum oxide abrasive to its super abrasive counterpart, CBN

What is Aluminum Oxide?

Aluminum oxide is the go-to abrasive for everyday grinding practices. It is manufactured by refining bauxite ore through heat treating. Additives including coke and iron are incorporated during heat treatment to create a furnace charge, which refines the mixture to produce aluminum oxide. You may be asking yourself, “Why is aluminum oxide the general purpose choice?”, and the answer is quite simple. This abrasive is ideal for grinding most steels and ferrous alloys, and is incredibly versatile. Aluminum oxide is a highly economic option as it is relatively inexpensive and hailed for its durability. However, being such a versatile material does lend to the idea that aluminum oxide must have its disadvantages as well. This material is not ideal for high speed grinding operations, fast material removal rates, or achieving tight tolerances. Aluminum oxide grit will dull over time, causing the abrasive on the grinding surface to form rounded fragments with greatly reduced bite.

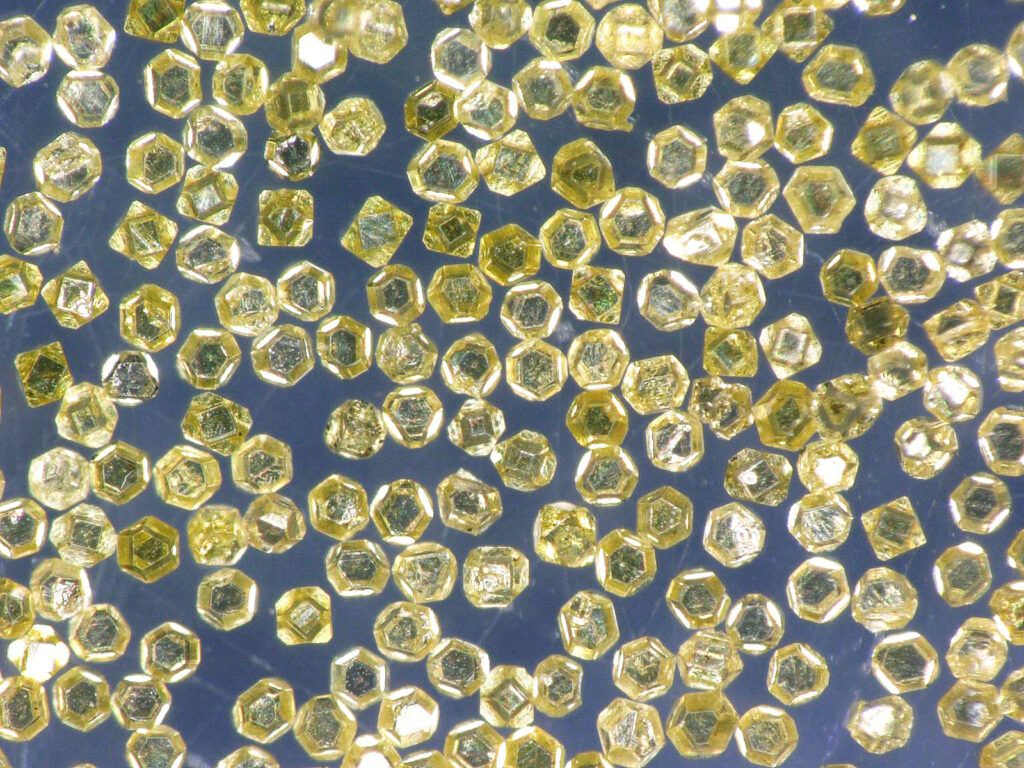

What is CBN?

CBN, or cubic boron nitride, is the second hardest material following synthetic diamond. Similar to synthetic diamonds, CBN abrasive is manufactured by heat treating hexagonal boron nitride and subjecting it to high pressure forces. By heat treating and pressurizing the material, a new crystal matrix forms creating high strength bonds between the boron and nitrogen atoms. The high thermal toughness index that makes CBN so desirable as an abrasive can be directly attributed to this new and improved crystal structure. Unlike diamond, which becomes malleable when exposed to high heat, CBN is incredibly resilient in high heat environments. CBN has gained considerable traction in the CNC industry as it is an ideal abrasive for tight tolerances and high speed grinding, as well as reliably providing a consistent surface finish. As mentioned previously, CBN falls very high on the hardness scale. It is so hard, in fact, that CBN is classified as a superabrasive. It is an ideal abrasive for cutting applications involving hardened ferrous materials such as steel and cast iron. In contrast, it is not recommended for grinding softer metals which will gum up the surface of a CBN wheel.

Which do I need?

After considering the individual advantages and disadvantages of aluminum oxide and CBN, it becomes clear in which applications each abrasive would be ideal. Aluminum oxide is the general purpose, catch-all abrasive. This material is the choice for hand grinding, standard manufacturing, and maybe even your DIY projects. It is cost effective, durable and versatile. CBN is the abrasive of choice for precision operations like CNC machining, high speed industrial grinding, and operations involving high heat capacity. This material accurately cuts cast iron and hardened tool steels like M2 and D2 with ease. CBN wheels make a great choice for manufacturers in pursuit of longer wheel life and fast paced material removal rates. In contrast, it is no surprise that CBN is a super abrasive.

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel