Diamond or CBN: Which Grinding Wheel Do I Need?

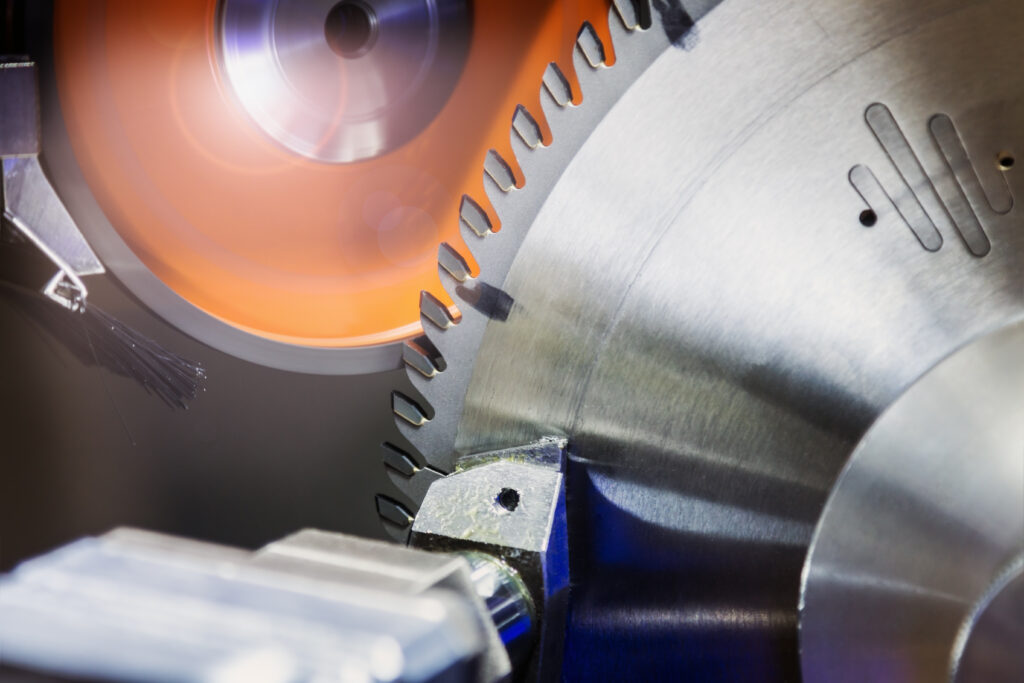

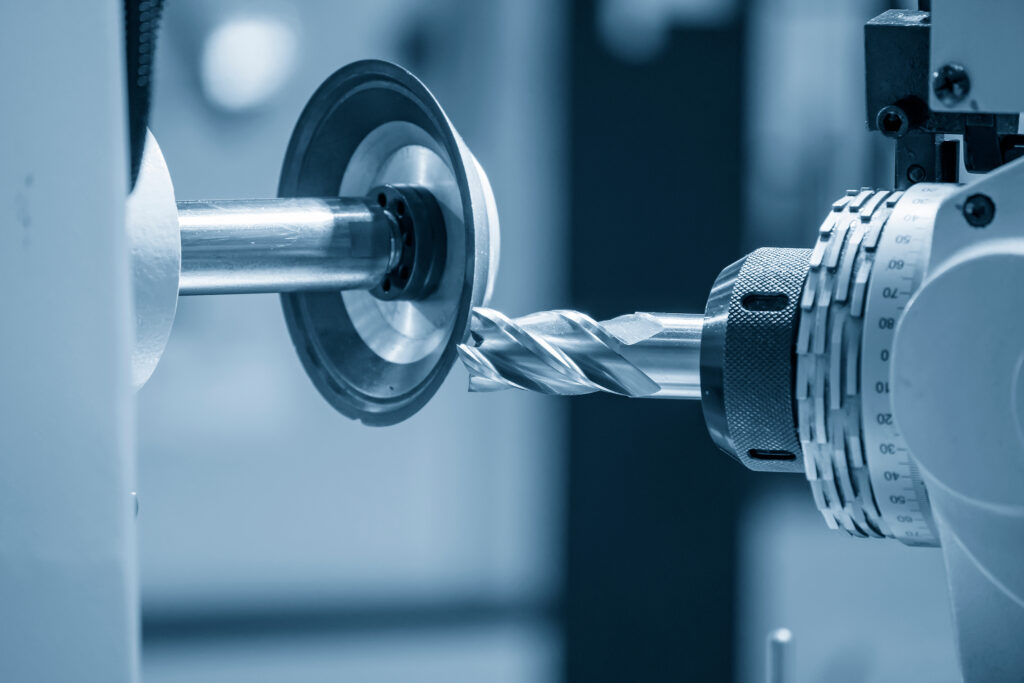

Identifying the right grinding wheel can feel overwhelming when there are many technical aspects involved. One of the most important factors in application success centers around choosing the right wheel for the job. When comparing the actual wheels, CBN (Cubic Boron Nitride) and diamond wheels are much the same, however, the actual cutting materials are what differentiates the two.

How Diamond Grinding Wheels Stack Up

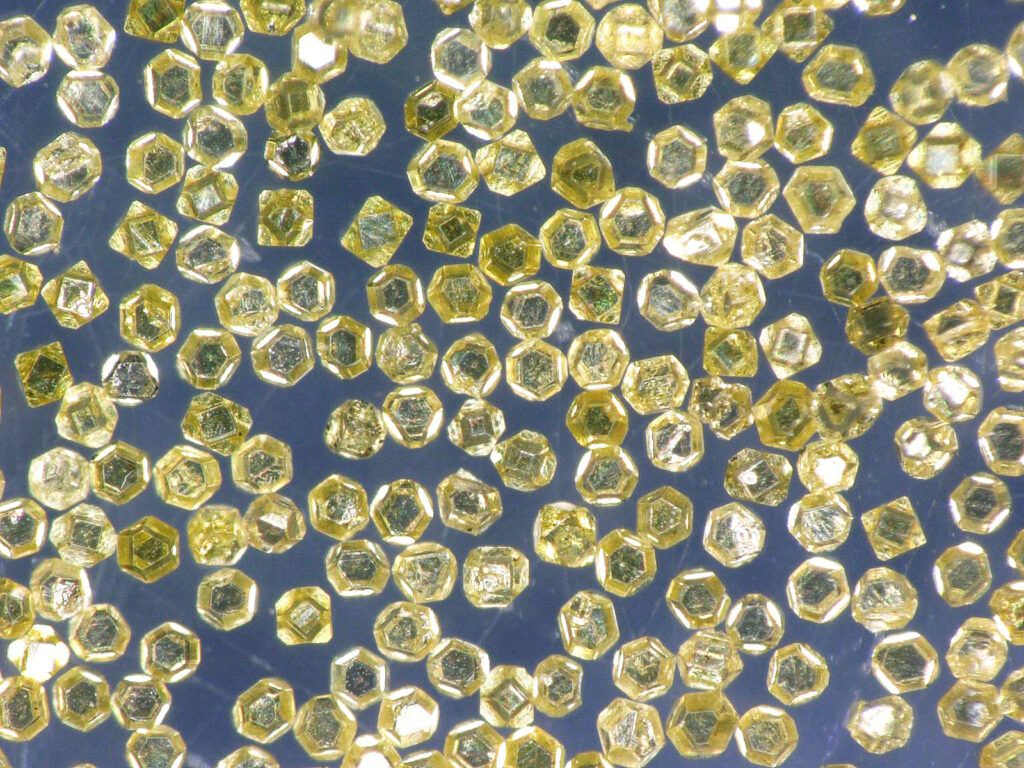

Peak performance of a diamond grinding wheel is achieved when grinding non-ferrous materials like carbide, glass, and ceramics. Even though diamond still takes the top spot when it comes to hardness, it isn’t always the best abrasive for the job. Diamond is not well suited for steel or iron because of the intense heat reaction created when carbon and iron collide at high speeds. The grit of a diamond wheel will quickly erode if subjected to ferrous materials. Overall, diamonds are great for most anything else. They effectively cut through ceramics, sharpen carbide, and polish granite.

If you’re looking to use a grinding wheel on specialty materials, diamond wheels are the go-to option. Here are a few advantages to consider:

A Unique Edge…

The distinctive makeup of a diamond is what contributes to its superior hardness. Diamond can take rough treatment, while still providing a fine cutting edge. Even though diamond appears to be fragile, it is still considered to be the hardest substance. A diamond grinding wheel can come in many different bonds, each one having advantages that distinguish the wheel itself and its applications.

Quality of finish

Without the correct grinding wheel, a top-notch finish is almost impossible to obtain. Many factors go into the machining process, leaving room for imperfections if not done correctly at every phase.

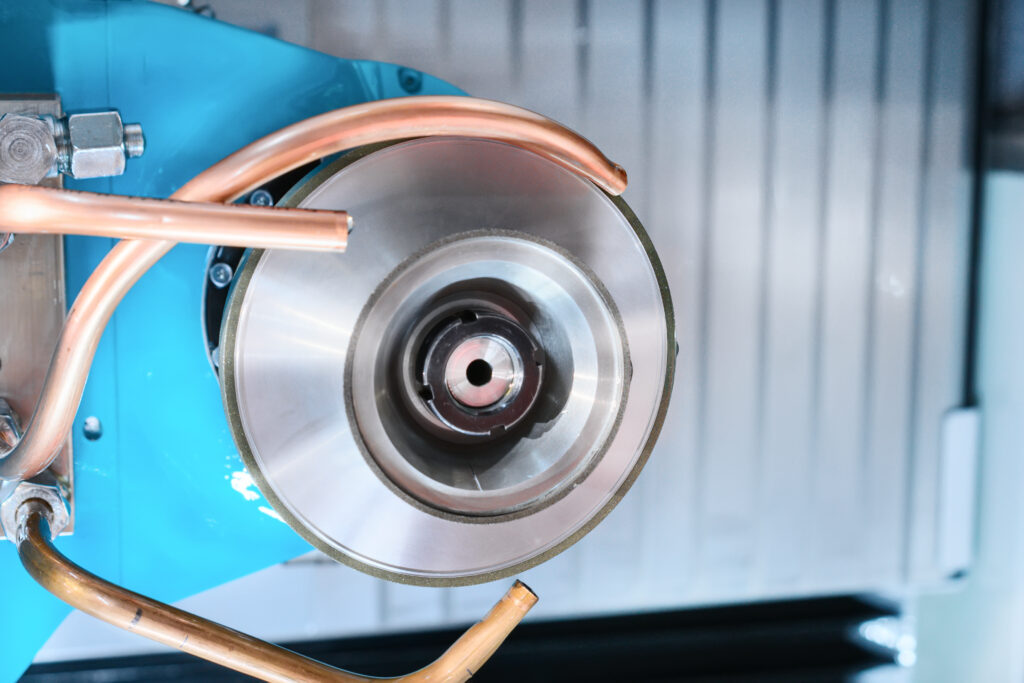

The use of a diamond superabrasive wheel is well-liked because of its precision, long life, and multiple application uses.

Longevity

Two factors set diamond grinding wheels apart from other abrasives: strength and longevity. While the cost of a diamond wheel may be more expensive than a conventional grit wheel, the extended life of a diamond wheel will recover that extra investment quickly. The bond of the diamond wheel can be adjusted to fit your unique needs, therefore extending the wheel life.

When are CBN Wheels Better?

When working with ferrous (iron-rich) materials, CBN is the superabrasive of choice. CBN (cubic boron nitride) is a highly-durable, synthetic abrasive mineral. This type of grinding wheel works best with steel or cast iron application. CBN doesn’t react as strongly to heat, making it the preferred choice for “heated situations”. Because of this, CBN wheels can be used on ferrous materials at high speeds without affecting the life of the wheel.

The Bottom Line

Diamond wheels are the hardest; but certainly not heat’s best friend. If working with ferrous material, choose CBN to avoid the chemical reaction that will quickly wear diamond.

In the end, superabrasive wheels are not “one-size-fits-all”. Each industry requires their own type of wheel to create the desired result based on the material being ground. Identifying the best wheel for the job involves identifying the materials you want to work with and what result you’re looking for. Based on this information, we can assist you in choosing the type of wheel that is most efficient for your company. Our application engineers are standing by to give you the advice you need to reach your grinding goals. We can be reached by phone or email to answer your questions.

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel