Diamond and CBN Dressing and Truing: What You Need to Know

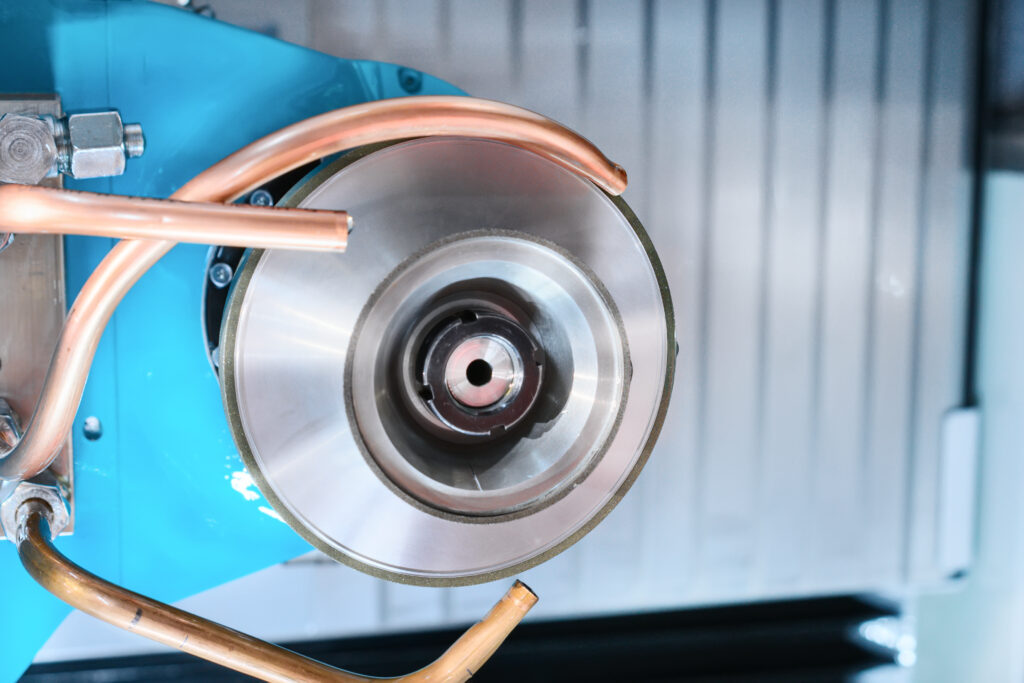

If you are experiencing poor grinding performance, improper dressing could be the blame. On occasion the diamond and CBN wheel surface has to be conditioned. The conditioning of your grinding wheel may include dressing, profiling and sharpening.

Loading happens.

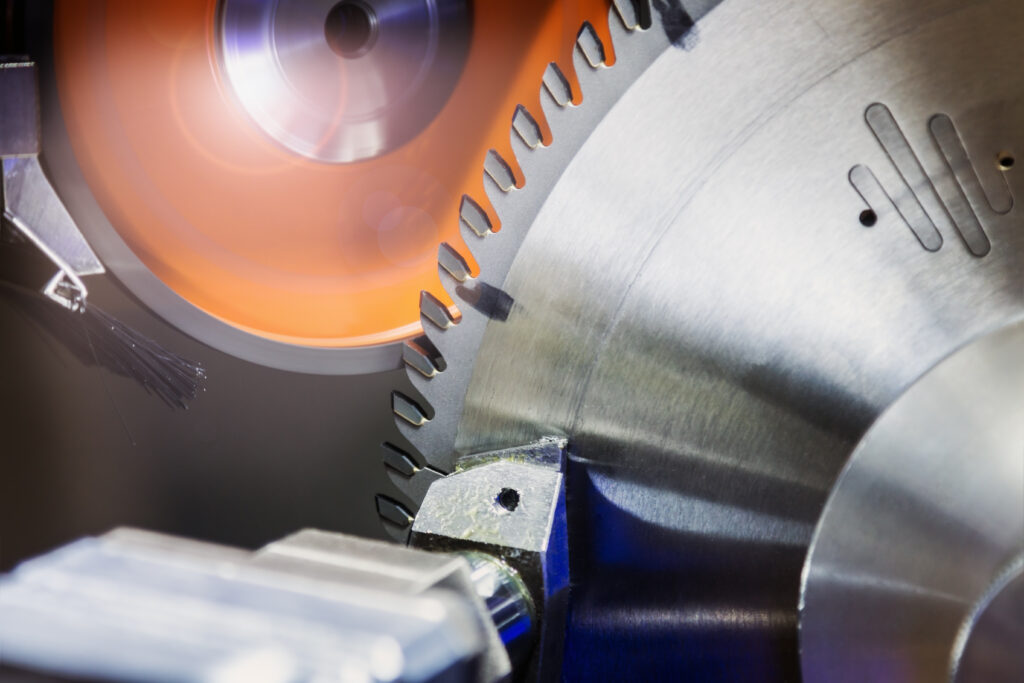

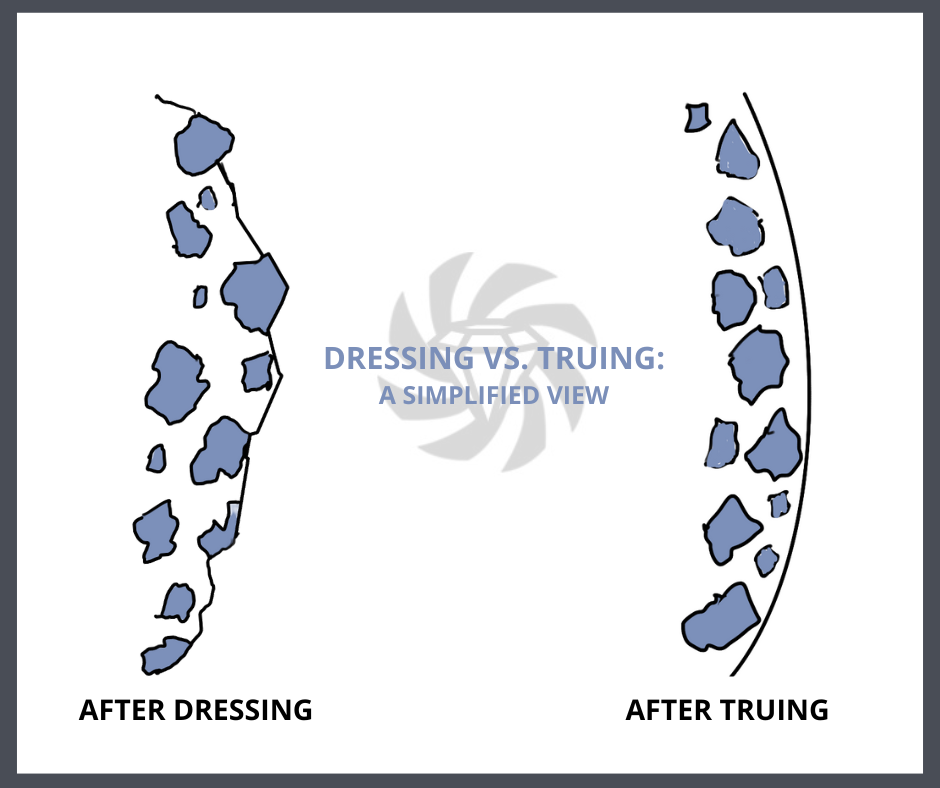

Much like sandpaper loading up with paint or debris after sanding furniture, a grinding wheel can become loaded too. Dressing your wheel becomes necessary to remove dulled grains and chips. Dressing the grinding wheel consists of re-sharpening the small, cutting edges of the wheel’s surface by fracturing the grains in order to create sharp edges. The space in between the grains are also cleaned out, removing material that has clogged the wheel’s face.

When using the proper dressing tool, you can create sharp cutting edges and recesses for chips simultaneously. A properly dressed diamond wheel will be true to the workpiece surface with open pores, giving the best results possible. Maintain optimal grain protrusion and sharpness on your diamond wheel by dressing regularly.

What is truing?

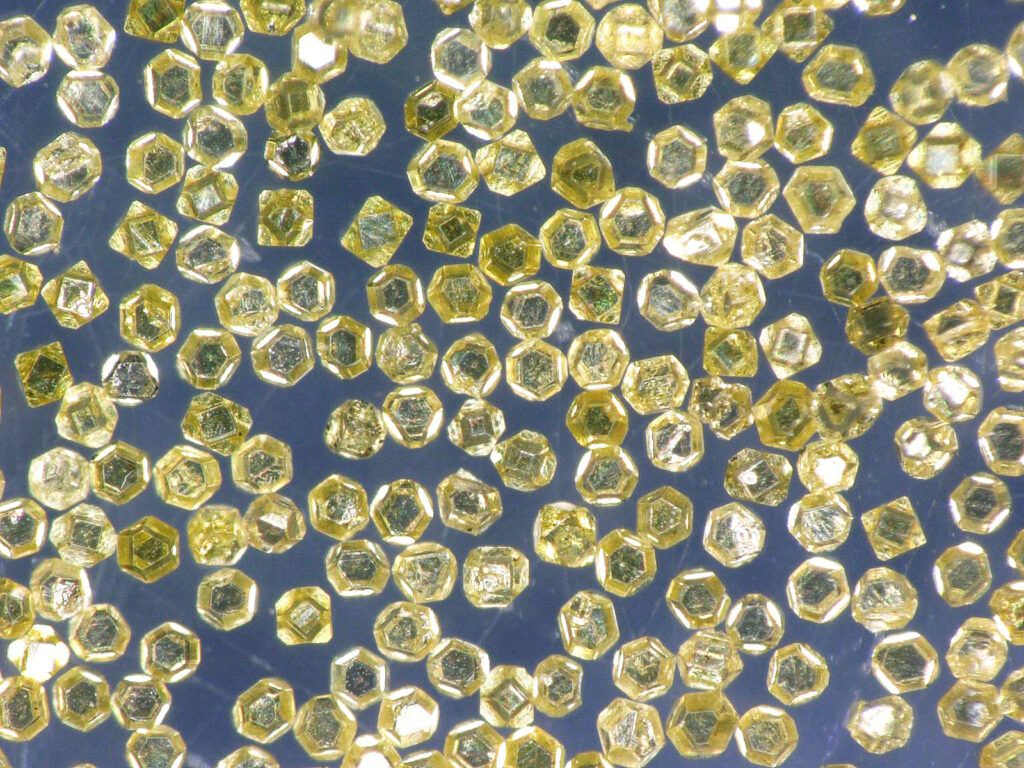

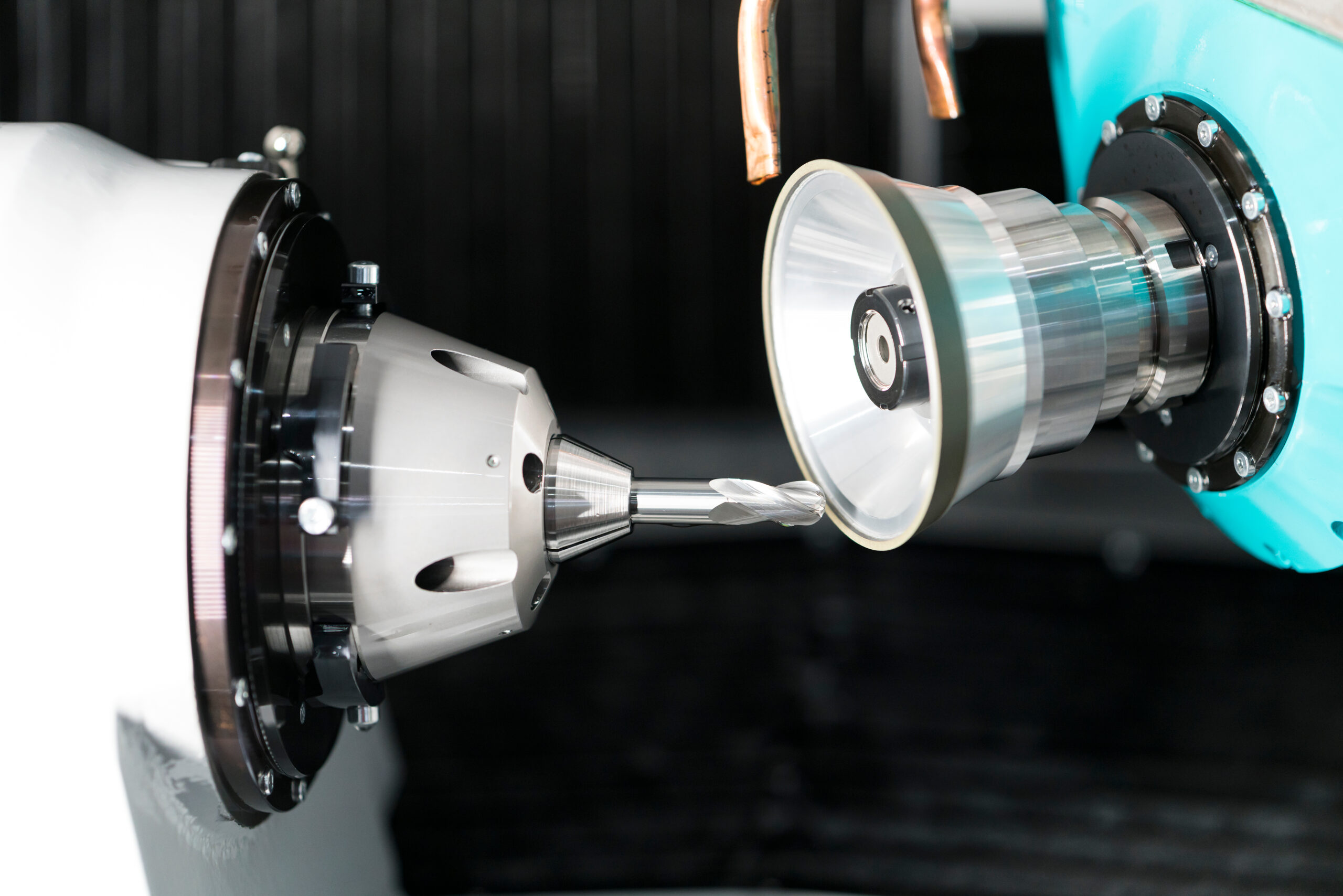

The truing process eliminates geometric deformities and gives the grinding wheel the required shape. Profiling diamond grinding wheels is economically efficient as the wheel can be used continually until there is no abrasive left on the wheel. Resin and hybrid bond diamond are usually dressed with silicon carbide or aluminum oxide wheels, a brake truing device, or a diamond roll dresser.

Dressing your Diamond and CBN wheels

- Use the dressing stick provided with the wheel or as recommended.

- Make sure to use a grit that is finer than the grit of your diamond or CBN wheel.

- Turn on the grinder and allow the superabrasive wheel to reach full RPM.

- Make sure that the dressing wheel traverses all the way off the part before starting to move back across the part.

- Turn off the grinder, then immediately begin applying the dressing stick to the abrasive section with medium pressure until the wheel stops rotating. Repeat this step as many times as necessary to fully open the bond.

- The wheel is open when it requires little to no pressure on the dressing stick, or it feels like the stick is being pulled into the wheel. The amount of stick used will vary depending on the grit and grade of the grinding wheel.

Process for truing diamond and CBN wheels

- Examine wheel flanges and spindle with care, and make sure flange surfaces are flat, clean, smooth, and contain no damage.

- Check your machine spindle for run-out. Ensure it is less than 0.0002”.

- Mount your wheel

- Mark edge being trued with a permanent marker if desired. The wheel is not true until all marks are removed.

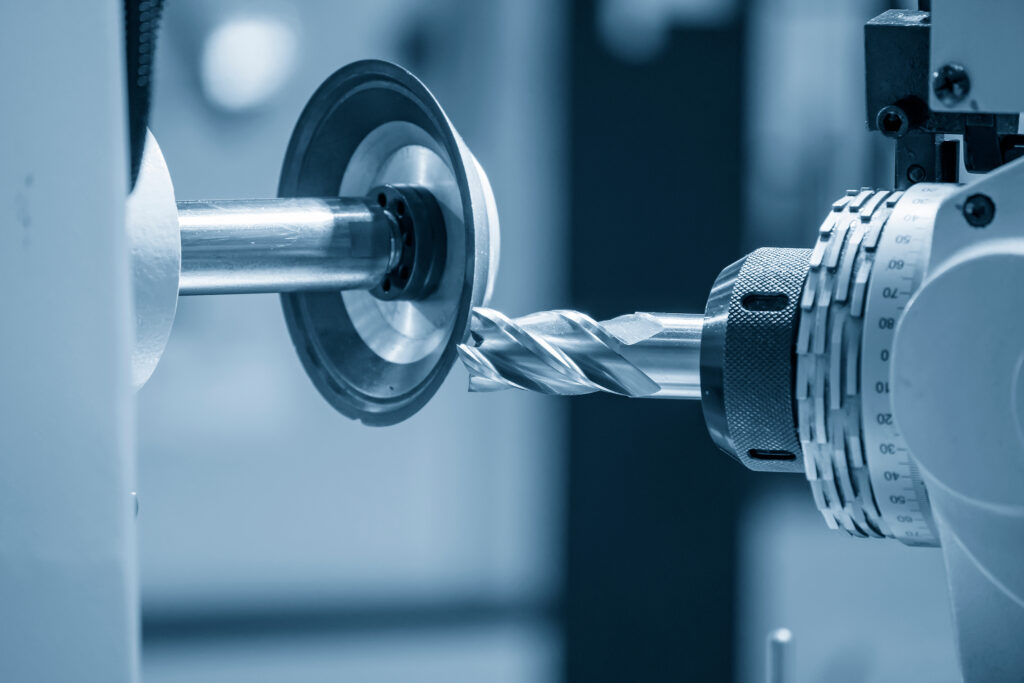

- Using a brake truing device/brake dresser:

- Start the diamond wheel at normal RPMs

- Tap the brake dresser wheel so that it is spinning with the diamond wheel.

- Bring the two wheels together until they touch – make sure the truing wheel is spinning when contact is made.

- Traverse the truing wheel back and forth at a comfortable speed

- In-feed no more than 0.0005”/pass

- Continue until the wheel is true. Marker will be removed; if any still shows, this is a low spot in the wheel and the wheel is not true.

Whether you are looking for general guidance or are ready to get a quote, we are dedicated to helping you find the right solution – and if we can’t provide the exact wheel you need, we will let you know. Eagle values communication and we will never lead you on. We hope you’ll explore the ways our team can help your business realize its potential.

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel