Factors Affecting Diamond and CBN Grinding Wheel Prices

What factors influence the price of a grinding wheel? Probably more than you may think! When evaluating price, some of these factors will be obvious while others are sometimes unexpected. To help you gain a better understanding, we’ve put together an easy reference guide below.

Obvious factors

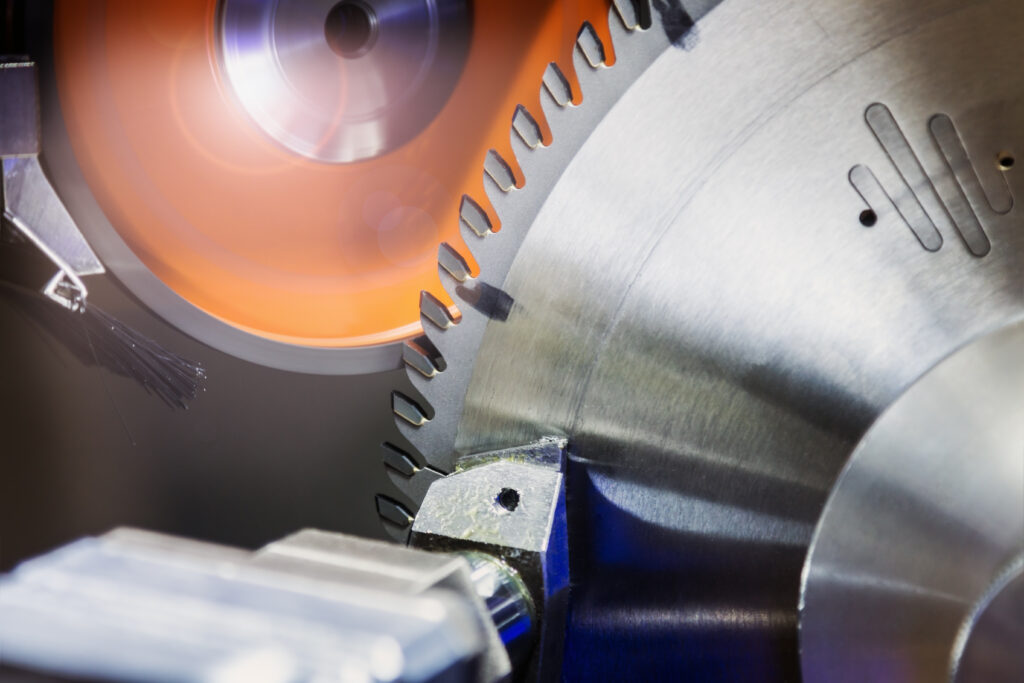

Diameter of the wheel – The larger the wheel, the more costly.

Thickness of the abrasive section – A thicker wheel contains more abrasive, making it more expensive.

Depth of the abrasive section – As with thickness, the greater the depth of the abrasive section, the more a wheel will cost. Increased depth results in more material being used.

Quantities – Most manufacturers use the “buy more, save more” model. The more abrasive and resin that can be mixed in one batch, the more cores that can be made. A larger quantity of one specific wheel typically decreases the cost of materials.

Unexpected factors

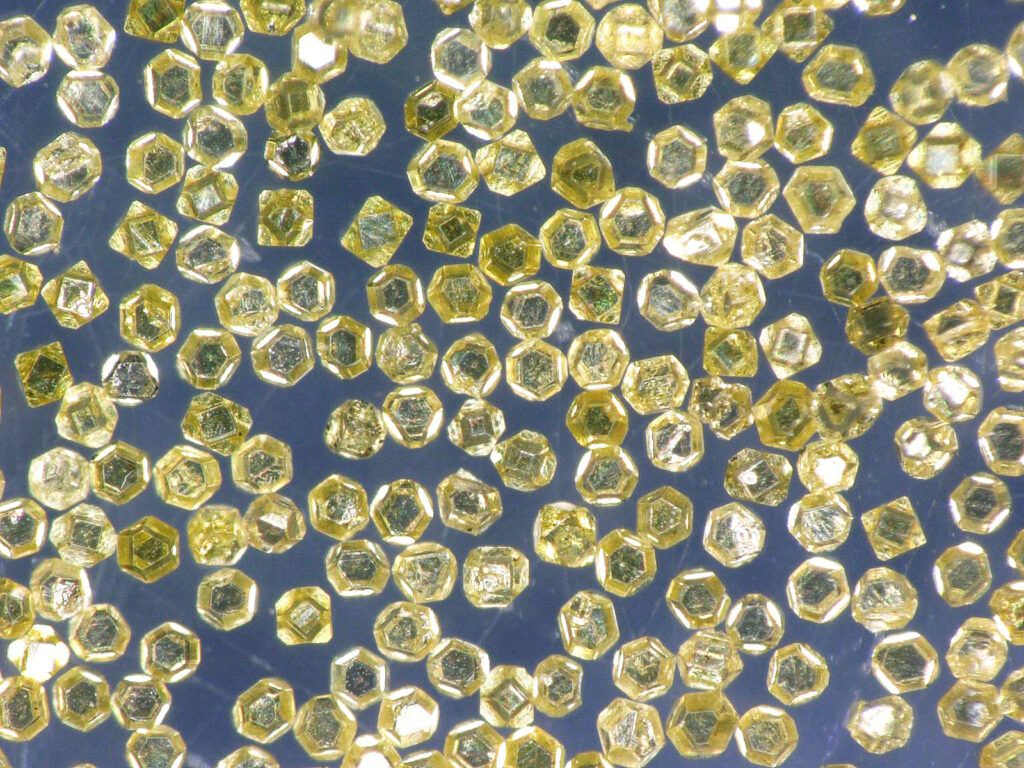

Concentration of the abrasive – A higher concentration C100 or C125 will increase the cost of the wheel; but for some applications C125 is necessary to ensure wheel performance. Concentration refers to the Carats / cubic centimeter.

Wheel bond – Some bonds are more expensive than others. The more costly bonds include metal bonds, poly bonds, hybrid bonds, vit bonds, electroplated and vacuum-brazed.

Grit size – Fine grits (400 and over) are priced higher.

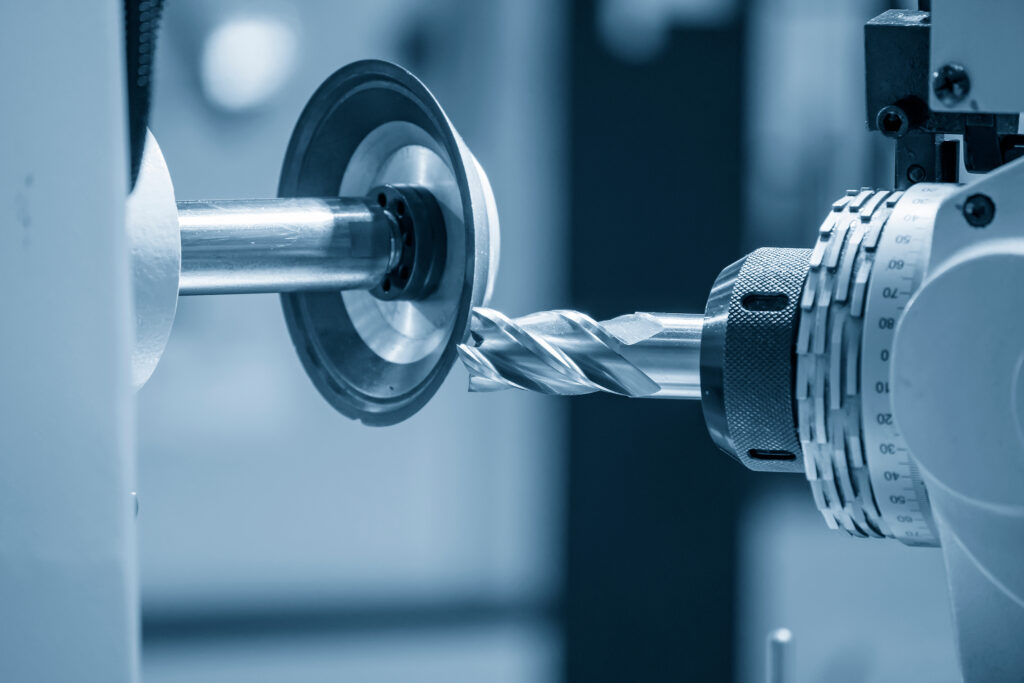

Tight Tolerances – Price will increase if the application or customer requires extremely tight tolerances.

Core Material – The material of the core can affect the pricing in two ways:

– Bakelite is typically the cheapest and the lightest so it saves on freight.

– Steel is more expensive and the heaviest, therefore increasing shipping costs.

So How Much is a Diamond or CBN Wheel Going to Cost?

As you can see, the cost of a superabrasive wheel can vary greatly depending on type and application. The above points will hopefully aid you in assessing the “total cost” of both pre-stocked and custom grinding wheels. Remember that your investment in a grinding wheel doesn’t only include the wheel itself; it also includes the value your wheel provides over time.

As you approach manufacturers, make sure you are prepared so that you can make the most informed decision possible. If Eagle’s solutions appear to meet your grinding needs, know that our expert Application Engineers will walk you through the process, answering any questions you may have. We provide free grinding wheel quotes directly from our engineers. We believe in a no-pressure environment to provide you with the education you need to guide you in the direction of the best grinding wheel solution.

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel