In our last post, we covered the subject of changing suppliers, and the cost of staying still. Even when the data shows that change is necessary to either fix a current problem or mitigate the likelihood of future loss, many companies choose to continue with their current supplier, but why? It is commonly thought that reaching out to a new supplier will initiate commitment and pressure to buy. Maybe you are ready to explore a change, but the “what ifs” are keeping you stuck. Does this sound familiar? You’re not alone.

There are many common fears companies have about switching grinding wheel suppliers. Most often they include questions like:

- Will this wheel perform as well as the old one?

- Are custom options more expensive?

- Am I going to experience delays because of it?

- Will I get support?

We can help provide the answers. Though every company is different, we want to address each of these fears– and when you’re ready to reach out, we will be here.

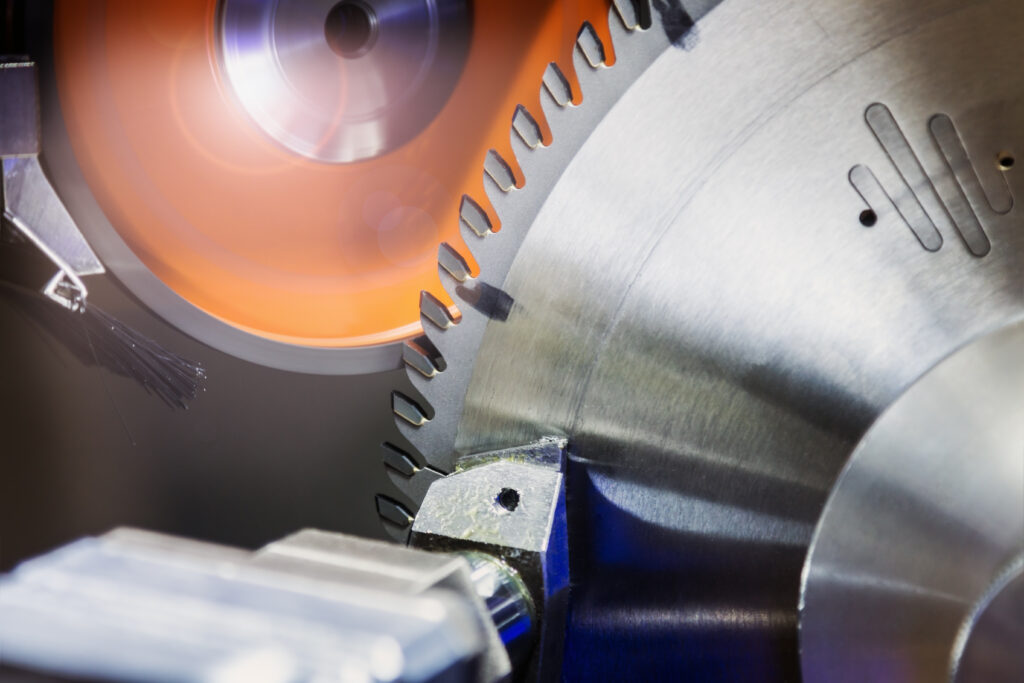

Will this wheel perform as well as the old one?

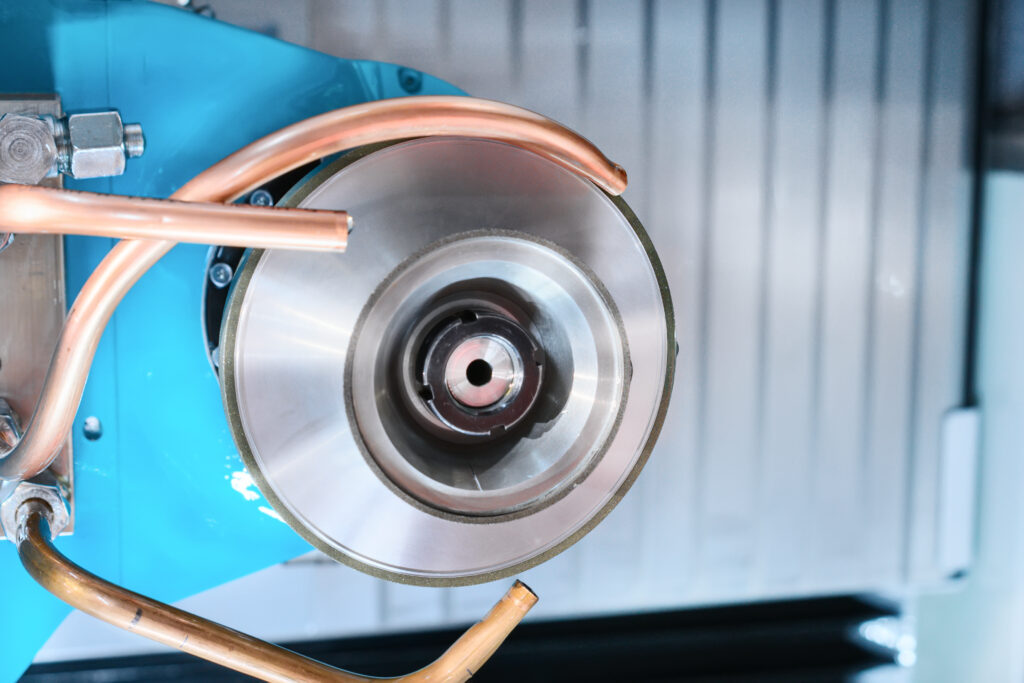

When we work with you to formulate a new grinding wheel, our engineers will gather as much information as possible to assure you have the best wheel for the job. If the wheel needs improvements, we will continue to provide support until it’s right. We outline our testing process here.

Are custom options more expensive?

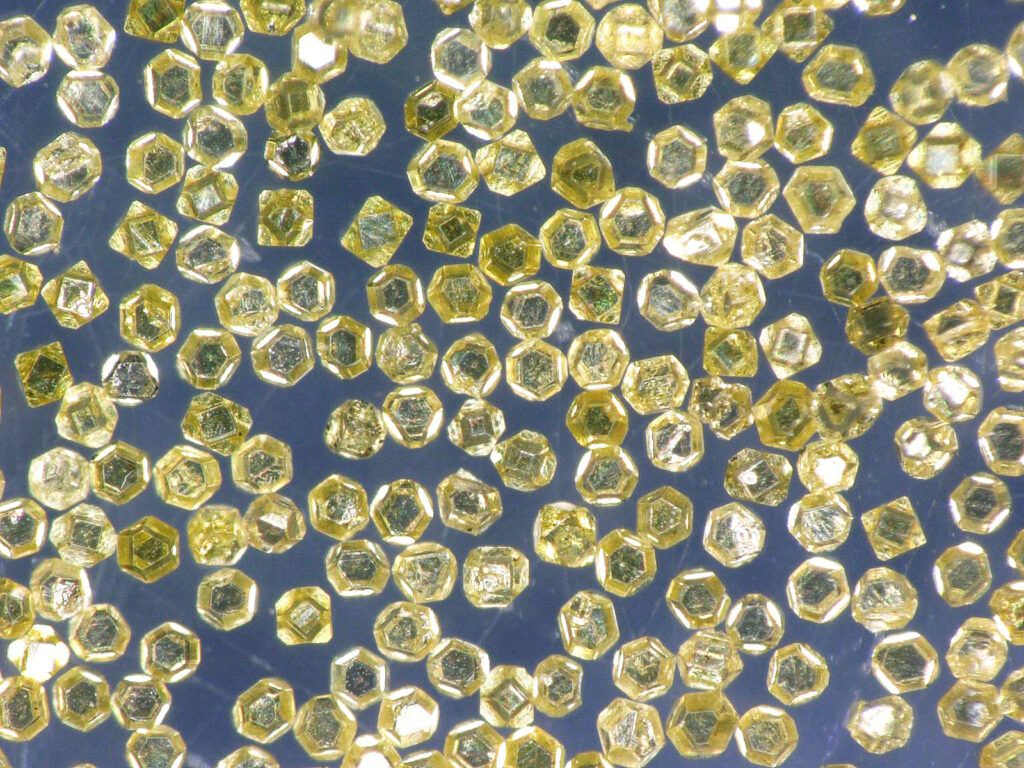

We customize wheels specifically to achieve the best grinding performance for the application. Our wheels are proven to perform at the highest level, giving customers life and stock removal that other vendors’ standard wheels just can’t match. We want you to test our wheels against what you are currently using, as it is the best way for you to see what our wheels can do straight out of the box. Sometimes we may have to tweak the bond slightly or modify the diamond or CBN, but ultimately, our aim is to improve your grinding or cutting operation. We do not charge extra for a custom wheel.

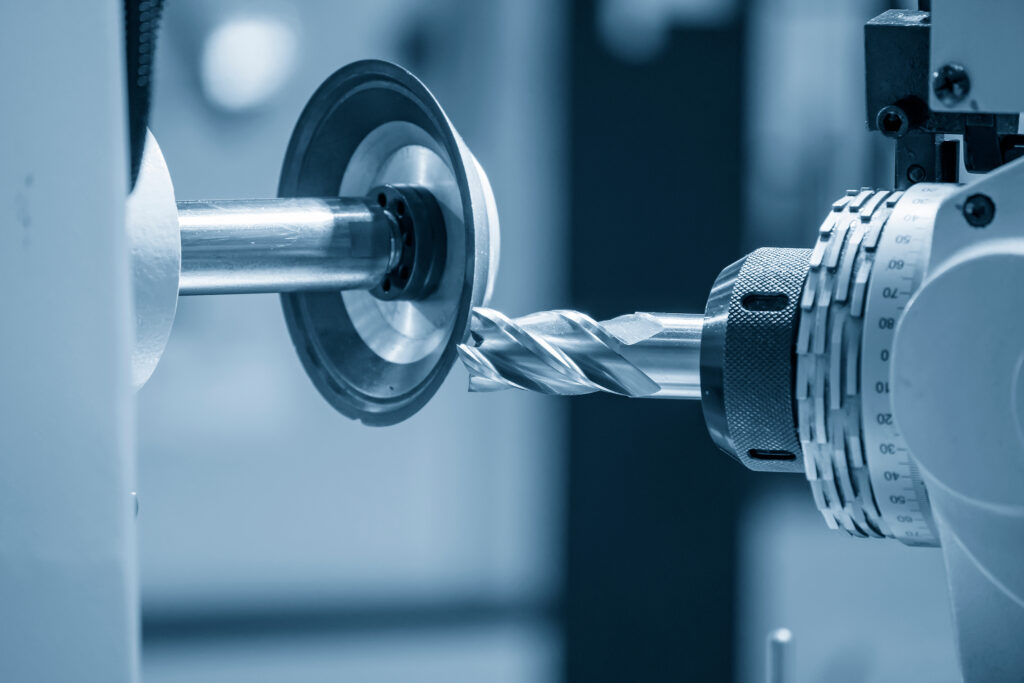

Will I experience a delay?

Switching suppliers doesn’t have to mean a long lead time. While electroplated, metal, and some vitrified bonds can take longer, we are able to expedite and will make sure that you get your new wheel as quickly as possible. Our customers benefit from our Make and Hold inventory program, which guarantees you always have a wheel on the shelf.

Will I get support?

Yes. You can be sure that Eagle can meet your demands without having to call multiple suppliers and being given the runaround or false promises. When you call, you will talk to an application engineer directly!

We provide:

- A pressure-free conversation with an engineer who has the knowledge to ask the right questions.

- Engineers that will ensure the grinding wheel meets (or exceeds) your standards.

- A team that speaks your language, no matter how technical or nuanced, and understands your desire to balance technical needs with the speed of delivery.

- Transparent communication that enables you to meet operational requirements without overly sales-focused conversations.

- Competitive pricing without sacrificing product quality.

Whether you are looking for general guidance or are ready to get a quote, we are dedicated to helping you find the right solution – and if we can’t provide the exact wheel you need, we will let you know. Eagle values communication and we will never lead you on. We hope you’ll explore the ways our team can help your business realize its potential.

contáctenos para una cotización gratis

o llámenos al 33 31255419 – 33 36315374

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel