Have some questions about glass grinding? You are not alone.

Choosing the right diamond wheel for your glass grinding needs can be the difference between consistent high-quality parts or loss of production and decreased efficiency. Inefficient grinding wheels will result in hours of lost production time — something that comes in between you and your operational goals. Whether your glass grinding operations include beveling edges for automotive glass or cutting glass tubes, take a look at our “cheat sheet” for everything you ever wanted to know about glass grinding– and how Eagle is staying ahead of the curve.

General Information

WHAT SHOULD MY WHEEL DO?

The goal of a high-performance glass grinding wheel is to cut freely with minimal chipping and to hold its profile for as long as possible. Correct wheel formulation is critical to the success of your operation.

INDUSTRIES

Glass grinding is used across multiple industries, but the most common include automotive, medical (tubes), construction (windows, glazing), optical glass, photovoltaic glass, electronic glass (cell phones, automotive touch displays).

TYPES OF GLASS

Annealed glass, heat-strengthened glass, tempered glass, laminated glass, leaded glass, soda-lime glass, borosilicate glass, armored glass, and more.

Technical Considerations

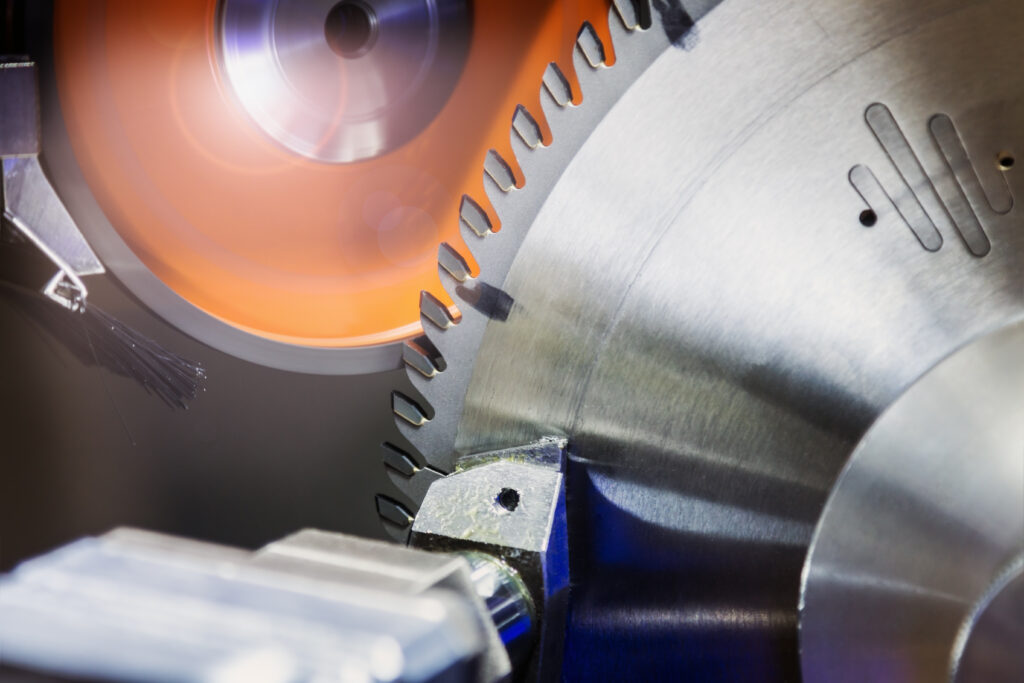

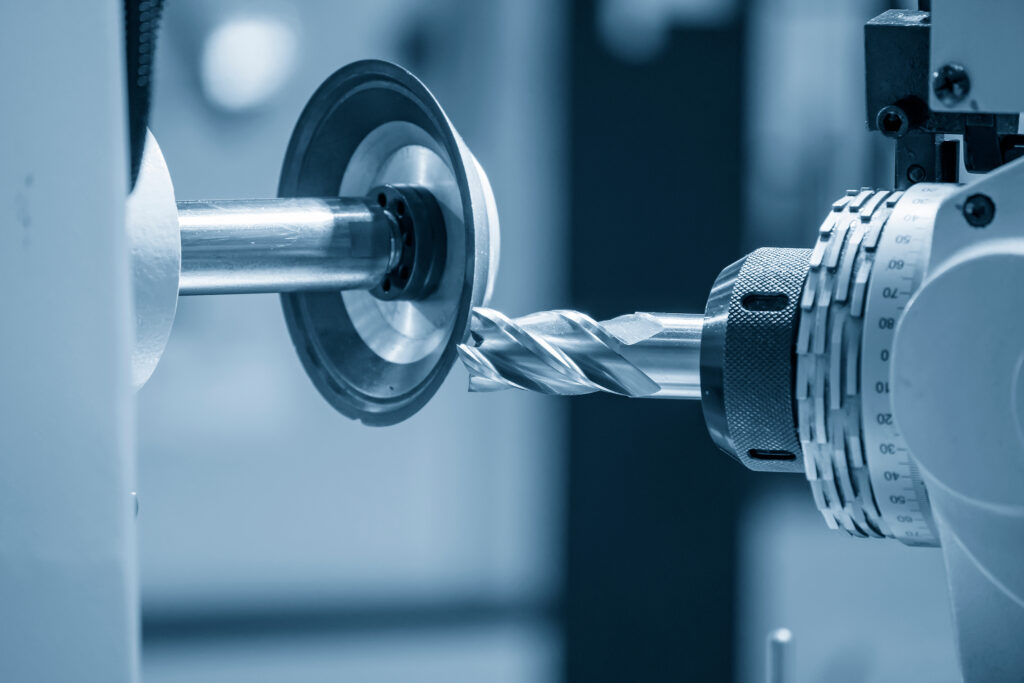

COMMON MACHINES

Bavelloni, Bovone, Bystronic, Glaston, Benteler, Glassline, CMS.

MACHINE REQUIREMENTS

Depending on the process, rigid CNC machines are typically needed allowing minimal vibration to keep tolerances to a minimum. High power motors are needed to drive metal bond wheels.

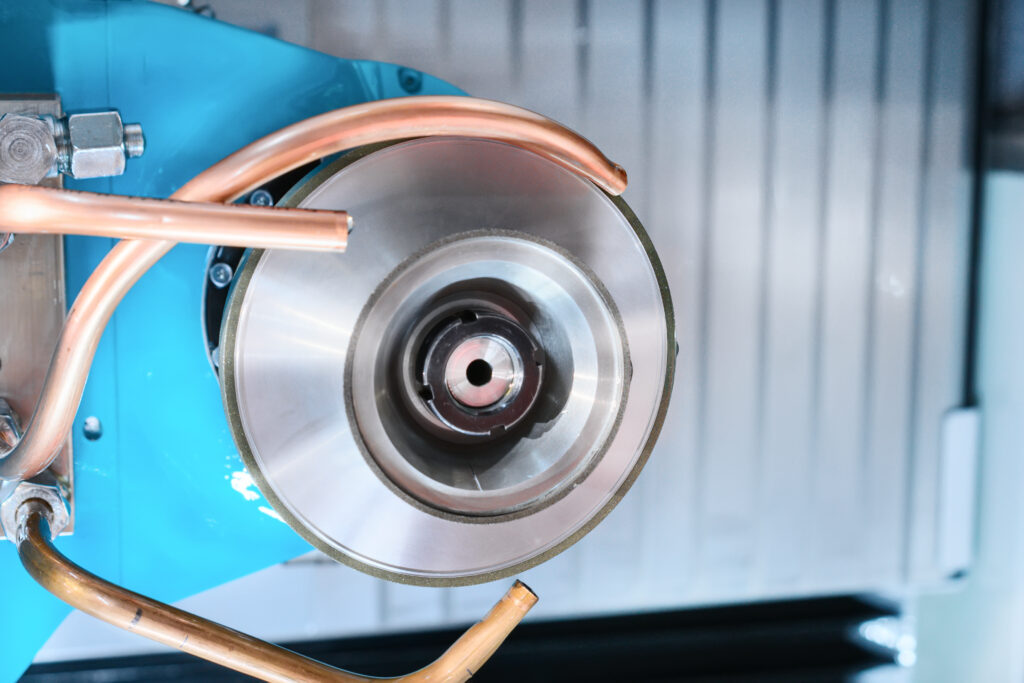

WHEEL RIM TYPES

Segmented, semi-segmented, continuous (with or without coolant holes).

COMMON BONDS

Metal is the most common, used for long production runs for roughing and finishing. Resin is used for shorter runs. Rubber bonds are used for polishing.

WHEEL SHAPES

There are many wheel shapes used in glass processing. Typical shapes include, but are not limited to, 1FF6Y Pencil edge with three common profiles (VA, PE, FA). These are typically used for beveling auto glass. 1A1R are used for cutting or slotting.

TYPICAL GRIT SIZES

120, 150, and 180 mesh.

COOLANTS

Water-based. Typically filtered via centrifuge to remove grinding particles.

TYPICAL RUN TIMES BEFORE RE-PROFILING IS NEEDED

10,000 meters. Reprofiling is normally done with a wire EDM machine.

Glass Grinding Wheel Requirements

MUST HAVES

Wheels must cut freely with minimal chipping yet maintain shape. Edges of glass are inspected several times during a production run to ensure any chipping is within allowed tolerances. A glass grinding wheel must hold its shape because downtime from wheel changes necessitate halting production. Typically sets of wheels are ready to be placed on a machine immediately, but unanticipated retooling should always be the exception. In most full production beveling operations, wheels are used for a specific amount of hours regardless of the amount of life left on the wheel. This way the wheel change is anticipated and can be done as efficiently as possible.

OTHER IMPORTANT CONSIDERATIONS

When purchasing a glass grinding wheel, consistency, performance, customization options, and dimensional accuracy are key. Eagle also offers a Make and Hold program so that you will always have a wheel in stock, as well as direct engineer support.

IS IT HARD TO CHOOSE THE RIGHT WHEEL?

With Eagle, it does not have to be. Glass grinding is not any more difficult to choose a wheel for than any other industry we manufacture wheels for. Our engineers will analyze your needs and performance goals and manufacture a wheel to achieve those goals.

COMMON PURCHASING MISTAKES

Remember that pricing isn’t everything. Eagle’s wheels are not always the cheapest on the market- and for good reason. Using an “off the shelf” wheel when something more custom would fit your application can cause time and loss of profit down the road. We calculate the cost per part produced with your current wheel and make a direct comparison to our wheel so that we can prove our wheel is more efficient. Learn more about our testing process here!

WHAT IF I BUY THE WRONG WHEEL?

Having the wrong wheel may cause machine downtime, falling short of production goals and inferior or scrapped parts. The wrong wheel also causes a constant need for wheel re-dressing, therefore more of the wheel is wasted during re-profiling.

Choosing a Supplier Partner

When selecting a supplier, ask yourself the following:

- Will I have access to application engineers?

- Is this vendor really assessing my needs or just making a sale?

- Will this wheel perform well in the long term?

- Can this vendor guarantee the required run time?

If you cannot get these questions answered, it may be time to look for a more qualified supplier.

So, What is Eagle’s Value?

SUPPORT WITHIN REACH

Grinding wheels and formulations can be complex- truly a scientific art. That is why you need dedicated, engineer support – not a robot phone system and unreachable salespeople. At Eagle, direct contact with engineers is as simple as a phone call, then engineers will answer the phone. We have incredible product availability and multiple global factories to meet your glass grinding wheel demands.

TRANSPARENCY

Eagle’s engineers believe in a no-nonsense, analytical approach. If we feel we cannot meet your goal requirements, we will tell you upfront. If we are confident in our abilities to help you reach your demands, we will partner with you to develop a wheel to maximize your productivity.

PROACTIVE

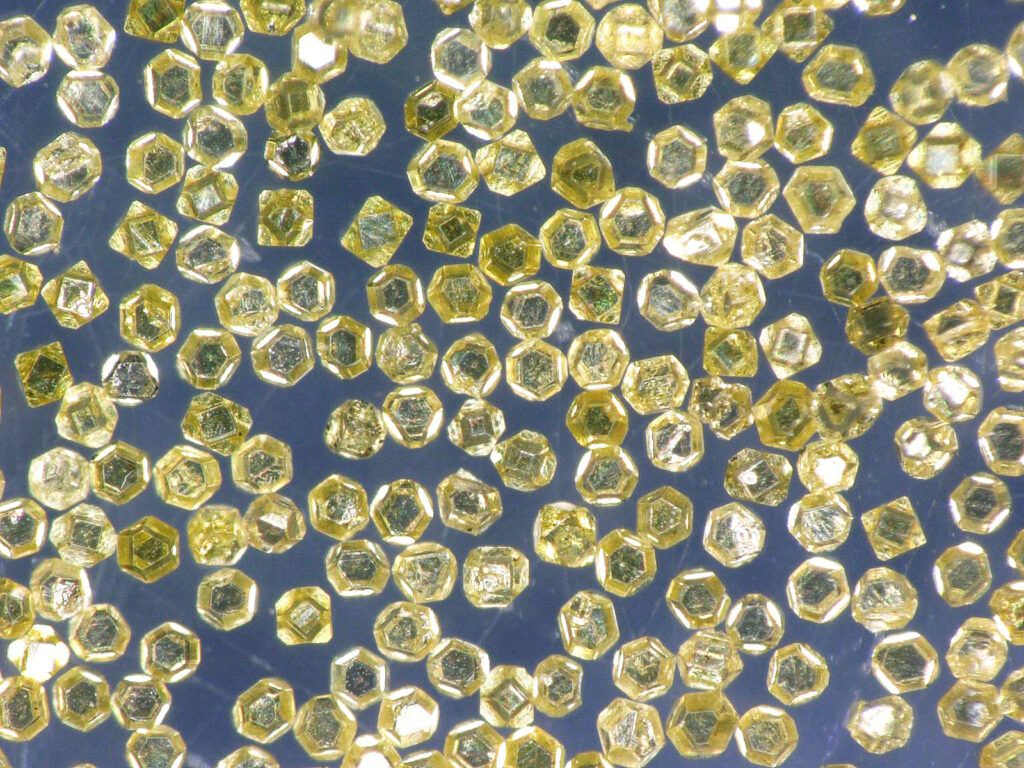

Does your current supplier keep ahead of the curve when it comes to new advances in grinding wheel formulations? For example, if a new type of diamond becomes available and is a proven success, we want to be proactive in offering this improvement for your company. We see companies using 10 or 20-year-old technology when there is a better solution out there. We do not believe in this approach! We like to see our customers with the newest bonds available to help keep them competitive in the global economy.

PEACE OF MIND

Stocking solutions are rare across our industry. We offer the perfect inventory solution (safety net) called Make and Hold. We produce your wheel ahead of time, making sure you always have one ready to go on the shelf.

Whether you are looking for general guidance or are ready to get a quote, we are dedicated to helping you find the right solution – and if we can’t provide the exact wheel you need, we will let you know. We hope you’ll explore the ways our team can help your business stay ahead of the competition.

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel

Grit Size & Impact on Performance: Engineer Interview