Grinding Wheel Applications – An Overview

What are the different types of applications?

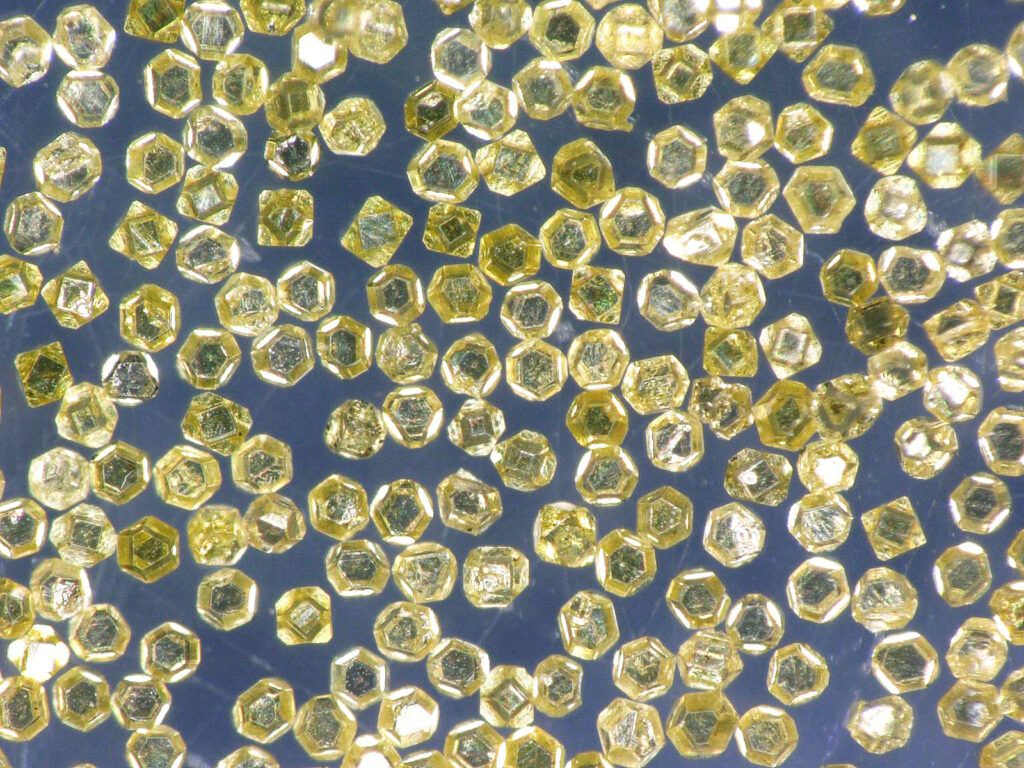

Superabrasive grinding wheels can be utilized for multiple applications across a diverse range of industries. From saw and tool cutting to electrochemical grinding, diamond and CBN wheels are able to provide maximum precision, longer wheel life and smoother finishes than most conventional wheels. The key to success, however, is to use the right wheel for the job. The abrasive used, bond and workpiece material all play a role in the overall formula. We’ve compiled an overview of common grinding wheel applications below to assist in identifying which wheel may best compliment your operation.

What are the different types of applications?

Diamond and CBN grinding wheels have multiple applications from cutting hard, brittle materials such as glass and ceramics to grinding steel and round tool manufacturing. As grinding wheel technologies continue to develop, the quality, precision and efficiency of the superabrasive wheel continues to evolve. Below we have listed some of the most common grinding wheel applications.

Surface Grinding

Surface grinding wheels are used to produce smooth finishes on flat surfaces. The process of surface grinding is used heavily in machining. The process typically includes a grinding wheel that is covered in abrasive particles (CBN, CDX or diamond) that cut chips of metallic or nonmetallic material from a workpiece, resulting in the face being flat or smooth. Our surface grinding wheels come in a variety of abrasive grains and can be manufactured on six different core materials – as well as multiple bonds. Surface grinding wheels composed of diamond or CBN are extremely hard and are capable of economically grinding materials, such as ceramics and carbides.

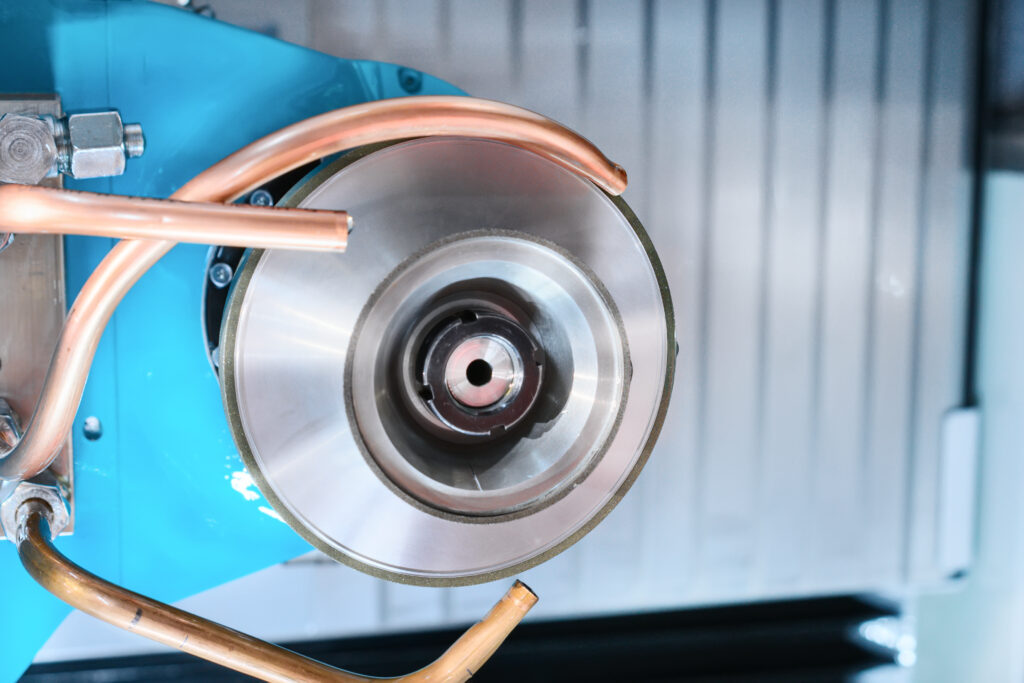

Electrochemical Grinding (ECG)

ECG can only be performed on workpieces made of conductive materials. Applications include tool steels, stainless steels, most chrome-nickel alloys and high-temperature alloys. In addition to being conductive, the material must be electrochemically reactive. For example, although platinum is conductive, it’s not electrochemically reactive enough for ECG. There are multiple benefits of ECG to include:

The ability to easily cut difficult-to-machine materials

Burr free cutting ability – the most important feature of ECG wheels

Operates at relatively low heat

Grinding wheels don’t require dressing

Can eliminate secondary processes

Centerless Grinding

Your workpiece can achieve exceptional roundness when using a centerless grinding wheel. The workpiece is supported by a work rest blade while sitting between a regulating wheel that rotates the workpiece and a rotating grinding wheel. Centerless grinding is typically used for grinding ceramics, magnetic materials, steel, PCD, PCBN, composites and tungsten carbide. Eagle’s centerless wheels can be custom made to fit your needs with our six unique bonds and a choice of multiple cores.

Periphery Grinding

The periphery, or flat edge, of the wheel is in contact with the workpiece, producing the flat surface. Peripheral grinding is used in high-precision work on tapers, simple flat surfaces, angled surfaces, slots, recessed surfaces, and profiles. Diamond and CBN wheels for peripheral grinding require a high level of geometrical accuracy as well as the ability to remove significant amounts of material. Periphery grinding wheels from Eagle put a premium edge on cutting tools and run at a higher Q-prime rate than our competitors.

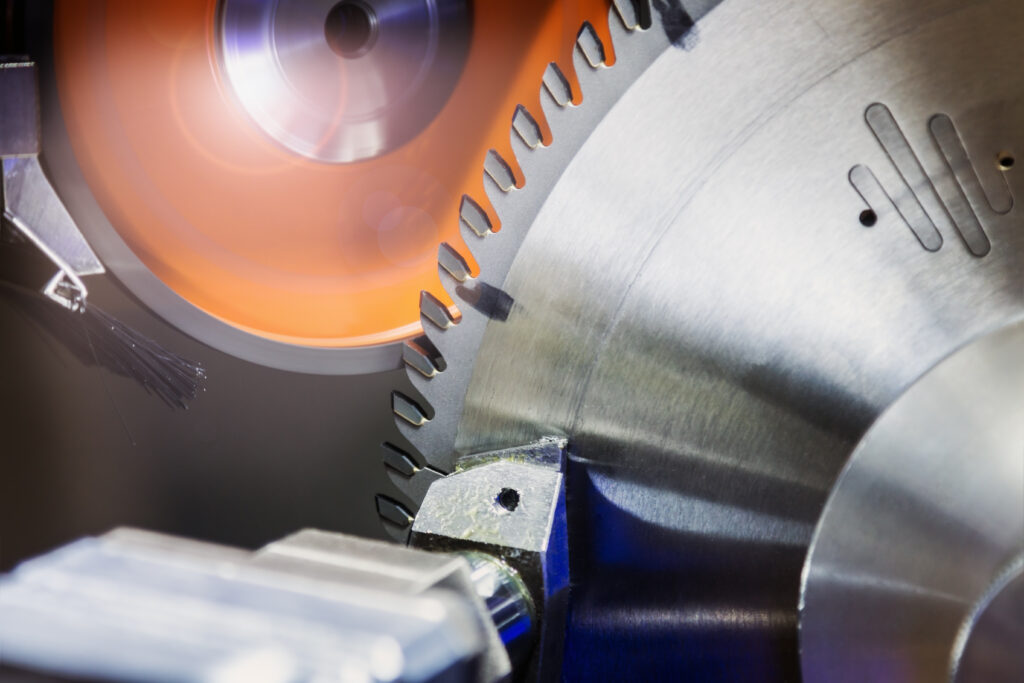

Cut-off

Cut-off wheels (also called cutting wheels) have different applications and structures than grinding wheels. Cut-off wheels are used for cutting on the peripheral surface of the workpiece. These wheels cut smaller workpieces at 90-degree angles, whereas grinding wheels grind large workpieces from a low angle. As a result, cut-off wheels are much thinner than grinding wheels, providing better accuracy and cleaner cuts.

Hardface & HVOF Grinding

Hardfacing is used to limit wear of metal parts by hardening their surface. Metal parts don’t typically fail because of fracture, but rather wear, causing the loss of dimension and functionality. Hardfacing is also referred to as “hard surfacing”, and works by applying build-up or wear-resistant coatings or materials to a part’s surface. Hardface grinding can be done on low alloy steels with carbon contents of less than 1%. Some of these include stainless steels, steels, manganese, cast irons, nickel and copper-based alloys.

Operations involving HVOF coatings require superior grinding wheel performance to achieve the best results. HVOF (high velocity oxy-fuel) coating is a thermal spraying technique in which melted or heated materials are sprayed onto a surface. Thermal spraying materials can provide thick coatings if needed. With such a high density and added thickness, maintenance and grinding of HVOF-coated surfaces require high-performance grinding wheels.

Saw and Tool Grinding

Eagle offers solutions for companies needing an array of grinding wheel applications. From service shops to filing rooms, our goal is to help you improve production continually. These may include band saws, knife sharpening, special steel tools, and carbide tools. Learn more about the benefits of using Eagle’s wheels in your saw and tool operations as well as the woodworking industry.

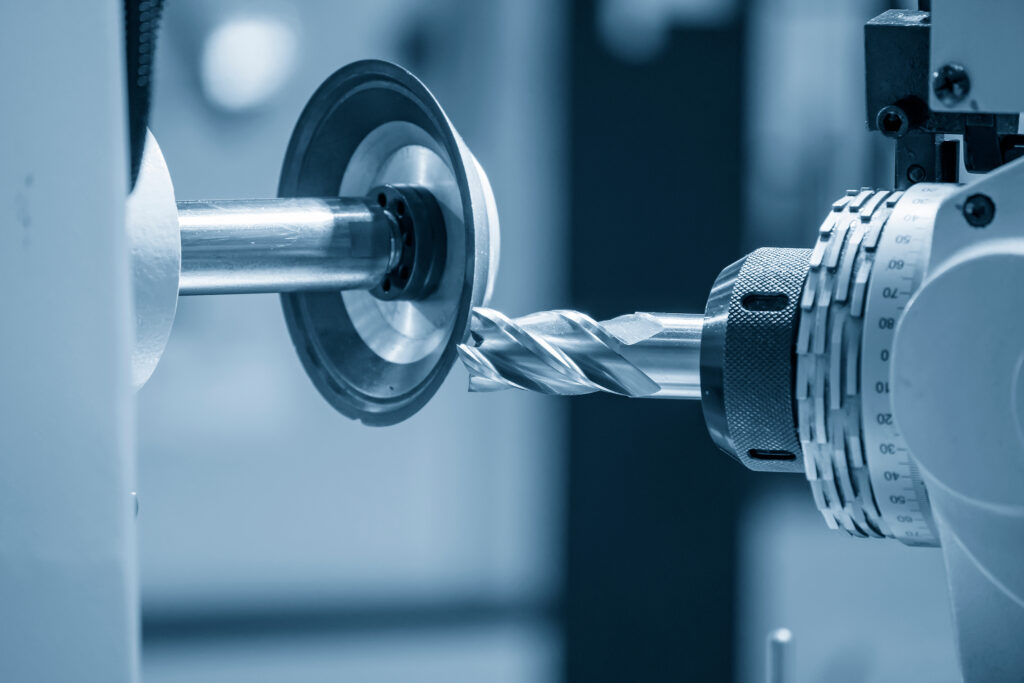

Round Tool Grinding

Round tool grinding may involve drills, end mills, reamers, stepped tools and other special purpose tools in varying geometries and designs. Round tool geometries are produced by grinding in successive production steps. A sequence typically begins with the preparation of the blank, followed by flute grinding, gashing and grinding of the clearance angle.

Flute Grinding

Flutes are the helical or straight grooves in the body of the tool. This provides a pathway to permit the removal of chips, and to allow coolants to reach the cutting surface. Flute grinding is an operation that pushes the limit of what a superabrasive wheel is capable of. The wheel is in full contact with a rotating tool blank, cutting the characteristic flutes of an end mill or drill. Fluting requires an aggressive wheel, able to handle the intense heat and forces generated by the deep grinding zone, all while maintaining its profile and leaving an acceptable finish.

Gashing

Gashing is grinding a slot or notch along the cutting face to allow for chip flow. Gashing is a challenging operation, requiring the superabrasive wheel to maintain its precise profile while still removing a large amount of material. It takes the right combination of bond, grit, and abrasive quality to ensure that the tool you produce is balanced, strong, and perfectly suited for its task.

Clearance Grinding

Clearance grinding involves grinding a small clearance, or relief angle on the face (tip) of the tool. Clearance grinding is a critical operation in any round tool manufacturing process. It ensures that the tool feeds easily and cuts smoothly. A superabrasive wheel used for clearance grinding must hold its shape while leaving an optimal surface finish and precisely removing material to achieve the proper cutter geometry.

Profile Grinding

Profile grinding can be carried out both in reciprocating and creep feed grinding. In the operation, the grinding wheel is dressed with the profile to be produced. The goal is to achieve the desired form and geometry tolerances of the workpieces. Available in many sizes and thicknesses, our diamond wheels are made specifically with the needs of profile grinders in mind. Whether the wheel has a full radius or square edge, it will be designed to cut efficiently while maintaining great edge retention.

Burr Grinding

Diamond grinding wheels can be used in the manufacturing of carbide rotary burrs (commonly referred to as rotary files) and are used for shaping, cutting, and grinding – as well as the removal of sharp edges and excess material (deburring). When choosing a diamond wheel for deburring processes, making sure that the wheel holds its shape is key. When a burr is spinning rapidly, it creates a chip that cuts off the material. That material and chip goes into the bottom (gullet) of the flute and ejects on the other side. The shape of the diamond wheel dictates the shape of the gullet. Should the gullet become rounded and not come to a point, the chip will not eject, thus creating a less aggressive cut. Burrs are used across multiple industries from medical to ceramics and foundry work. If you are looking to remove material fast, burrs are excellent tools.

How Can Eagle Help?

As you can see, superabrasive wheels are not “one-size-fits-all”. Each application requires its own type of wheel to create a unique effect based on the material it is applied to. Identifying the best wheel for the job involves identifying the materials you want to work with and what result you’re looking for. Based on this information, we can assist you in choosing a type of wheel that is safest and most efficient for your company.

Once our engineers work with you to formulate a grinding wheel based on your application, we invite you to test our wheels against what you are currently using. This is the best way for you to see what our wheels can do straight out of the box. Sometimes we may have to tweak the bond slightly or modify the diamond, ultimately, our aim is to improve your grinding or cutting operation.

Customer Results

The following results come from an actual customer who tested our wheels. Eagle helped this company achieve greater manufacturing feed rates and speeds after switching from a competitor.

“We were able to reduce the total run time by almost 40% (from 22 minutes to 14 minutes) and extend truing intervals by 4x (from 50 parts to 200 parts). With the competitor’s wheels, we were sticking after every five parts. With the new Eagle wheels, we do not have to stick wheels (only after truing to open it up).”

See more endorsements from our customers here.

Our application engineers are standing by to give you the advice you need to reach your grinding goals. We can be reached by phone or email to answer your questions.

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel