Resin Bond Grinding Wheels: Formulations & Uses

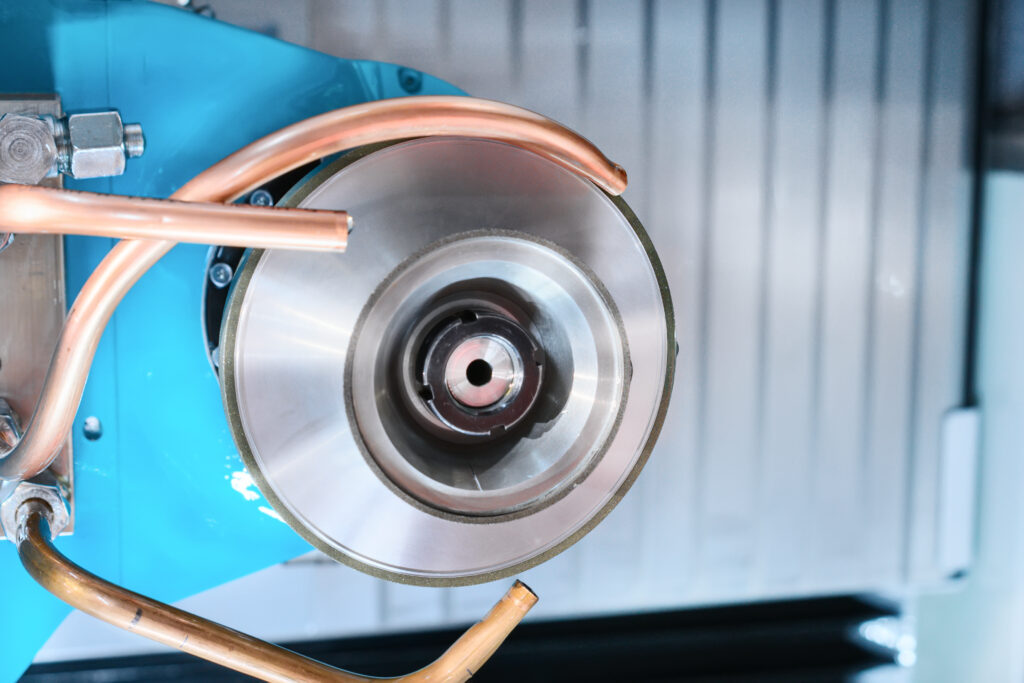

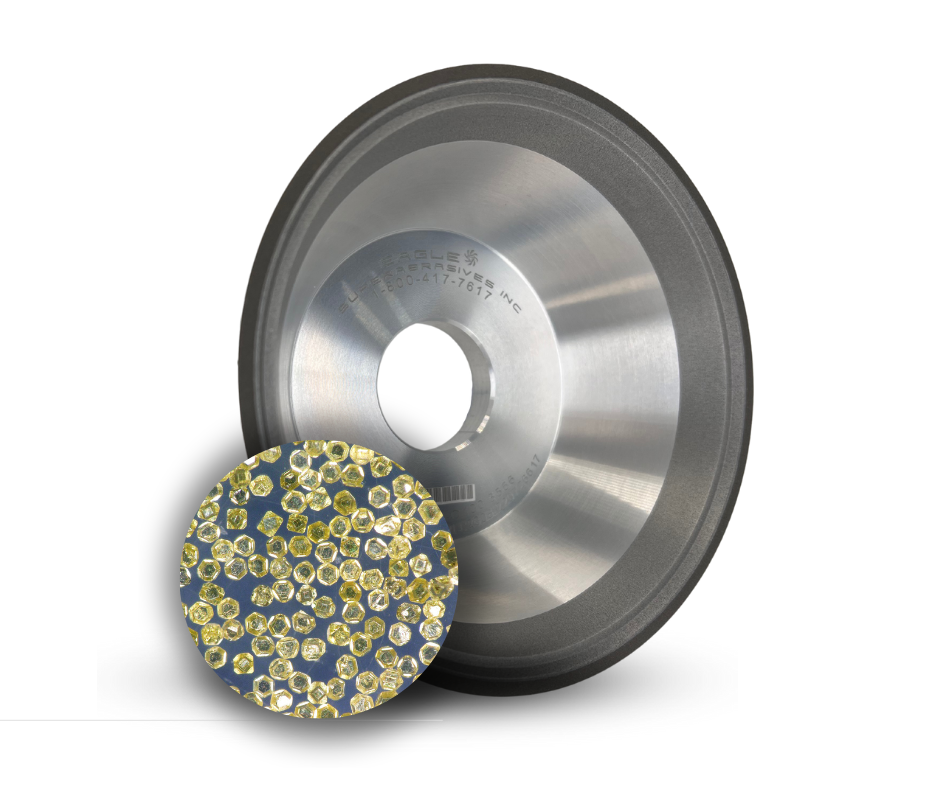

One of the most widely used grinding wheel bonds in the superabrasives market is the resin bond. Typically composed of either phenolic or polyimide resin, there are virtually limitless options in terms of ingredient concentration. But what is it that makes the resin bond one of the most commonly used bonds across the industry? Let’s dig deeper into each type of resin, their uses and advantages to further investigate the reason behind the popularity of resin across multiple applications.

Phenolic Resin

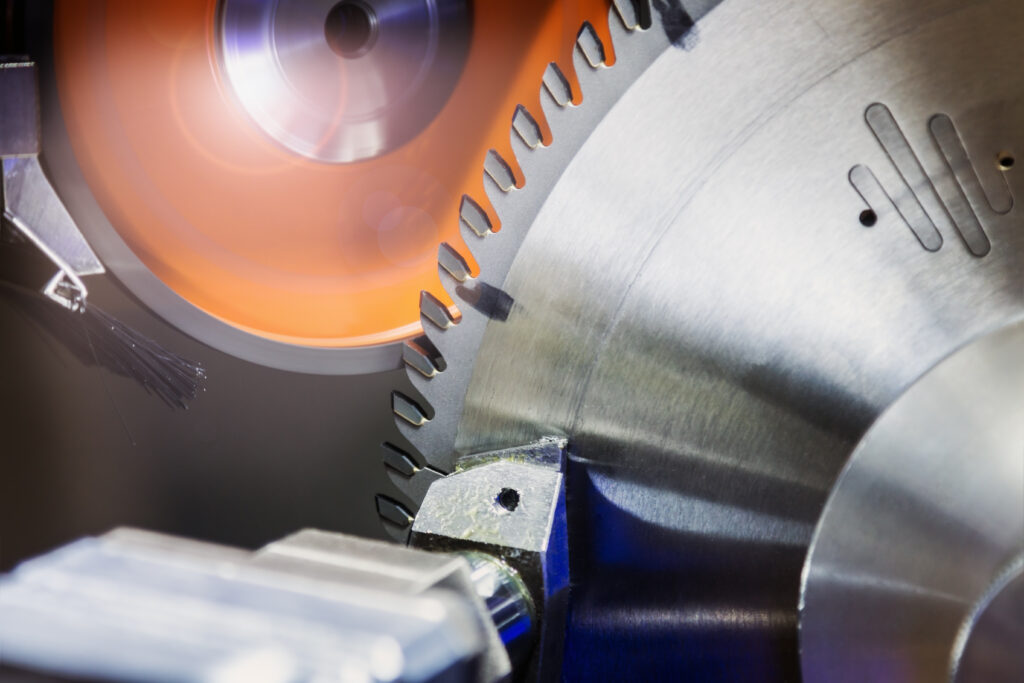

Phenolic resin is a synthetic polymer created using the chemical reaction that occurs when phenol is mixed with formaldehyde. This reaction facilitates the creation of a thermosetting network polymer, where the chains of the polymers interlink to form insoluble, hardened connections. The structure of the polymer chains directly affects the properties of the resin. In this case producing a more delicate, less heat resistant structure ideal for grinding softer materials. Phenolic resin bonds are often used in wheels for the woodworking and mining industries but are also a popular choice for general purpose grinding. Phenolic resin wheels work in both wet and dry grinding conditions and are also ideal for centerless grinding.

Polyimide Resin

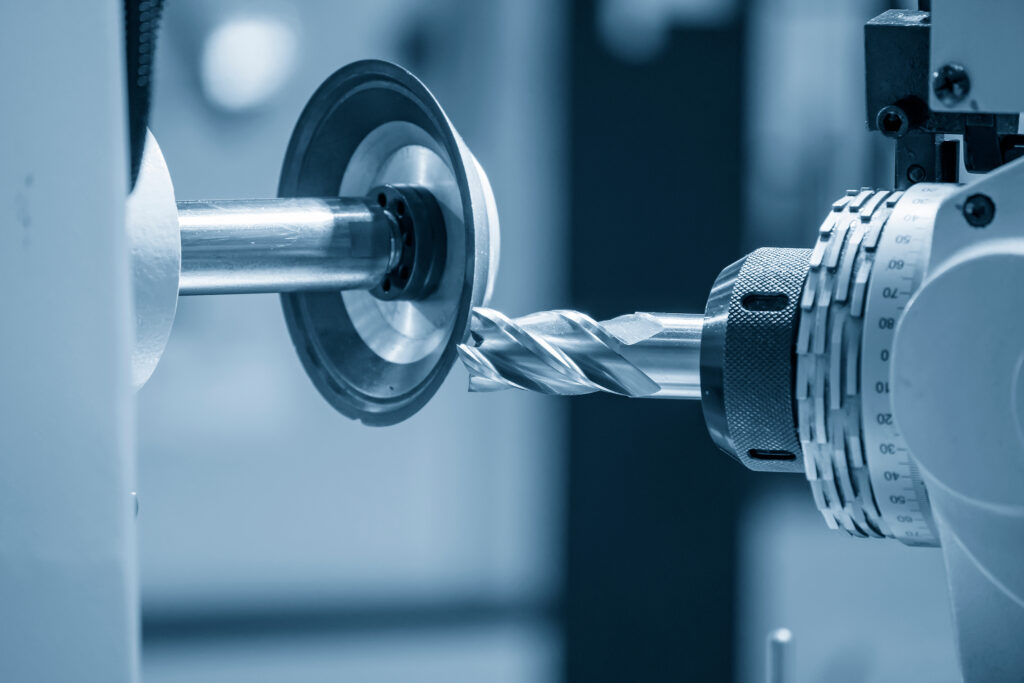

Polyimide resin is a high-performance plastic polymer. The product of a reaction between dianhydride and diamine, this material is hailed for its heat resistance as a soluble thermoplastic capable of enduring temperatures, from below zero to 400 degrees Celsius under dry grinding conditions and 625 degrees Celsius in wet grinding conditions. As a harder resin option with impressive thermal capacity, polyimide resin is ideal for high tolerance grinding. These wheels offer greater stock removal rates, better form holding, and excellent wear resistance compared to other bond types. It’s no wonder they’re a popular choice among manufacturers in the round tool, aerospace, and automotive industries.

Choosing Resin

Resin bond wheels are the choice for a multitude of applications across manufacturing, including automotive component fabrication, semiconductors, and paper converting wheels. The key distinction to make when choosing a resin bond lies with your type of machinery. If the application is correct and you are using a CNC machine, then a poly bond may be the best choice. If you are using a low-power machine to sharpen carbide-tipped tools, then a phenolic resin would be the best option. With their wide range of usability, high reliability, and cost effectiveness could a resin bond wheel be the right one for you?

The application engineers at Eagle offer years of experience to help create the perfect bond option for your specific grinding operation. We offer continued support even after the purchase of your wheel. Our engineers believe in continuous improvement, making sure that your grinding wheels are formulated to perform as efficiently as possible throughout the life of your grinding operation.

contáctenos para una cotización gratis

o llámenos al 33 31255419 – 33 36315374

Whether you are looking for general guidance or are ready to get a quote, we are dedicated to helping you find the right solution – and if we can’t provide the exact wheel you need, we will let you know. Eagle values communication and we will never lead you on. We hope you’ll explore the ways our team can help your business realize its potential.

Hard vs Soft Grinding Wheels

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel

Grit Size & Impact on Performance: Engineer Interview