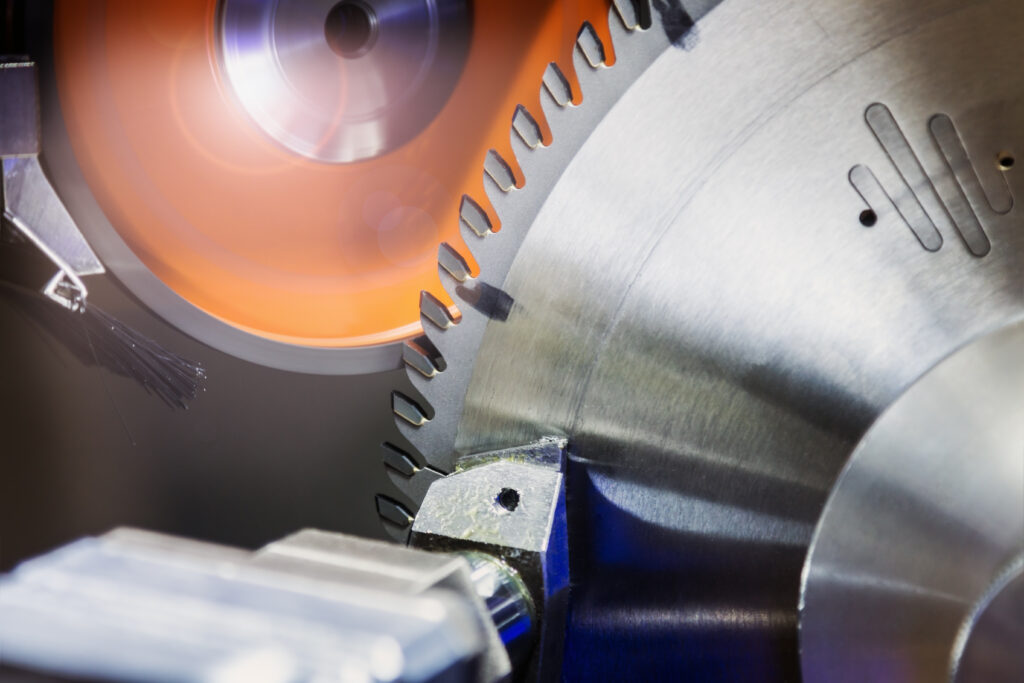

Can Diamond Wheels Maximize Saw Sharpening Profitability?

Have you considered the possibility that a custom diamond grinding wheel could be the key to taking your saw sharpening shop to the next level? Most people don’t think about the potential hit they could be taking when they don’t have the right wheel for the job. Over time, the results of the wrong wheel can really affect your bottom line.

Contrary to common belief, the production abilities of your diamond wheel is more important than the initial cost. While the life of the wheel matters, having a wheel that removes more material and increases output provides you with a much greater benefit.

A custom diamond wheel can positively impact your bottom line. In the example below you’ll see how implementing a custom diamond wheel into your grinding process can increase your productivity– as well as profits!

What happens when you purchase a cheaper wheel?

In this hypothetical scenario, we will look at a saw grinding business working 220 days per year with the average production rate of 60 saw blades per day, per worker.

Saw Sharpening Charge – $20

Diamond Wheel Cost – $200

In a typical work year, one individual can manufacture 13,200 saw blades.

The revenue generated from one worker alone equals $264,000.

The average diamond wheel lasts 5 days.

Based on 220 working days / 5 = 44 wheels needed per year.

44 wheels per year x $200 diamond wheel cost = $8,800 per year on wheels.

Let’s say our customer is looking to save 15% per diamond wheel.

If we reduce the cost of each wheel by 15%, the final price per wheel becomes $170.

Using the same formula, 44 wheels x $170 diamond wheel cost = $7,480 per year on wheels.

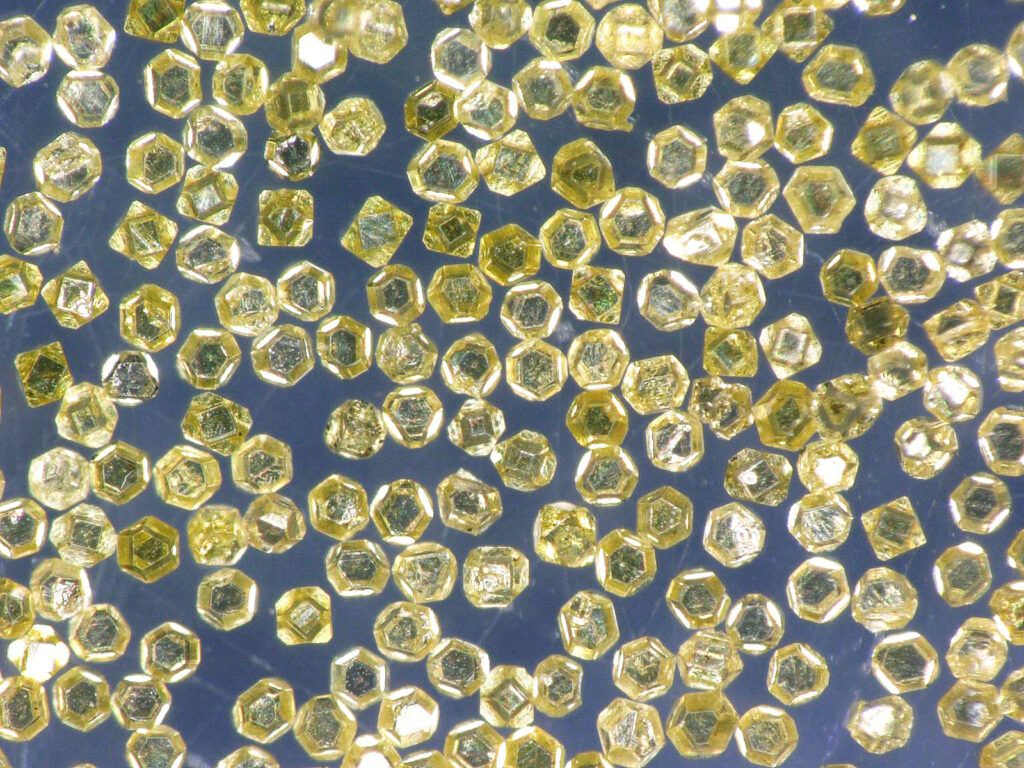

While saving $1,320 is great, making the wheel 15% cheaper likely means that cheaper diamond will be used, reducing the life of the wheel.

Let’s consider a different scenario.

What happens if you choose a longer lasting wheel?

Another customer looks to save money by having a wheel formulated with a harder bond to increase the life of the wheel- let’s say 30% longer.

30% longer would increase the wheel life to 6.5 days.

220 working days / 6.5 = 34 wheels needed per year.

10 less wheels used per year, saves $2,000.

While this savings may seem outstanding, there is a downside. The wheel becomes less productive due to its hardness. So, the actual revenue from service ($20 per saw blade) may decline due to less productivity.

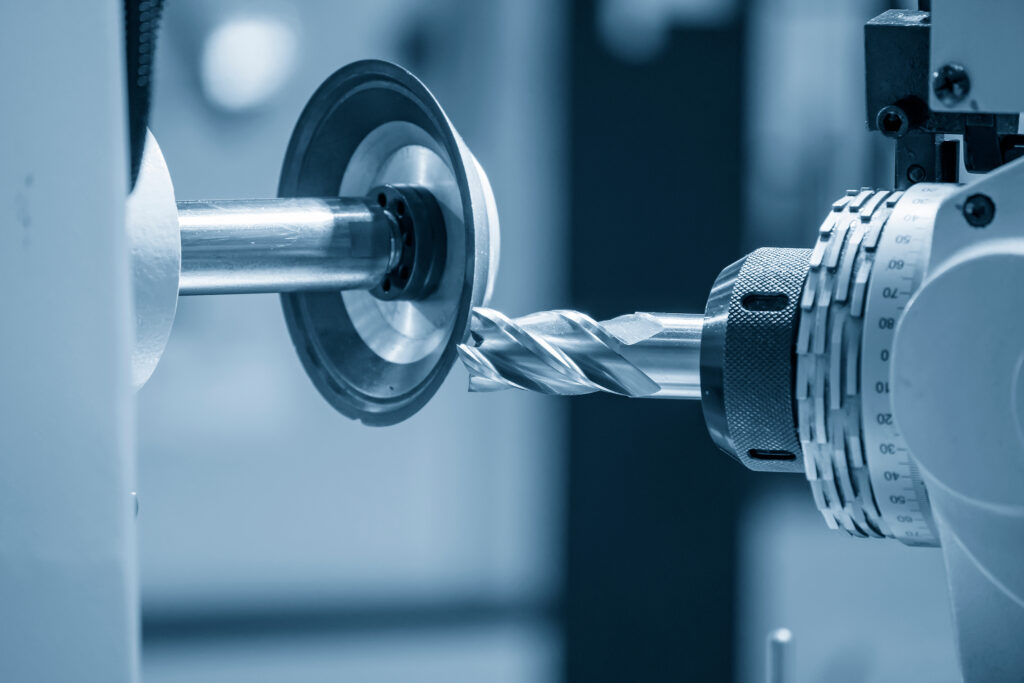

So, what is the answer? Manufacturing more blades per day.

The real savings can be found when you have a wheel that can manufacture more saw blades per day.

Let’s say Eagle formulates a wheel that can grind an additional 10 saw blades per day.

The 60 saw blades per individual worker now becomes 70.

An additional 10 saw blades serviced per day, generates an extra $200 a day in revenue.

70 x 220 working days = 15,400 saw blades serviced per year.

Comparing that to the first scenario of 60 saw blades per day we see the profits growing quickly.

13,200 saw blades/year vs. 15,400 saw blades/year

What is the bottom line?

When focusing on increasing output rather than reducing initial investment cost, there is an increased net profit of $35,200 by making the wheel more aggressive.

Our aim is to build wheels that can increase your production. Instead of having a wheel that is 5% cheaper, or lasts 20% longer, having a wheel that grinds more saw blades per hour actually produces more profit in the long run.

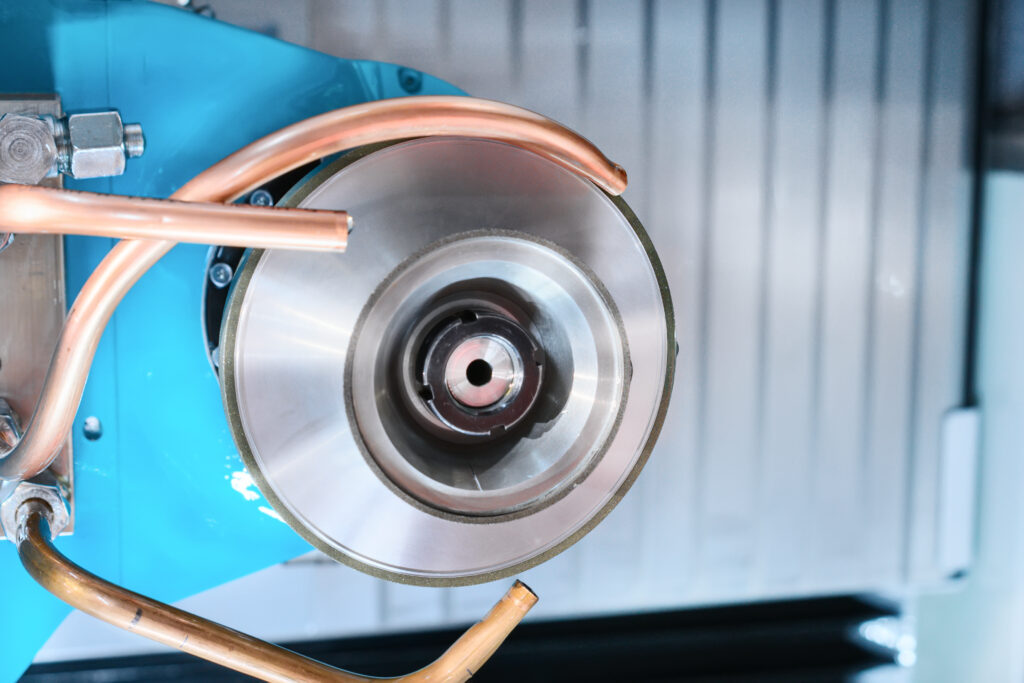

Eagle offers solutions for companies needing an array of grinding wheel applications. From service shops to filing rooms, our goal is to help you improve production continually.

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel