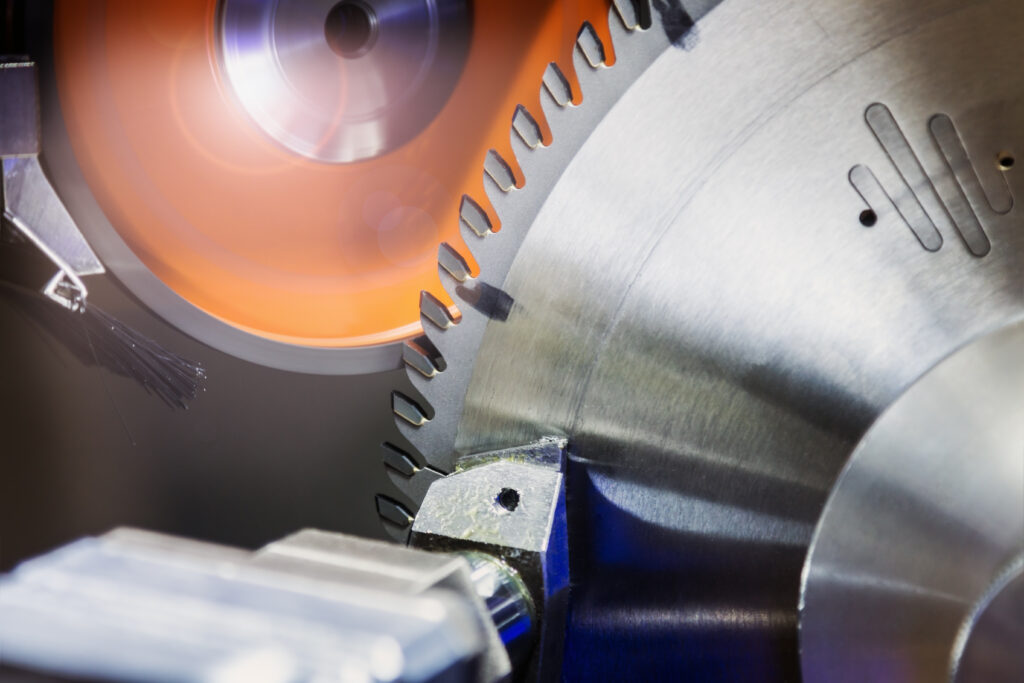

Known for its wear resistance, stellite is a cobalt-chromium alloy that has recently become a popular substitution for carbide in woodworking tools. As stellite becomes more common, many manufacturers are finding that it is a particularly precarious material to grind. Attempts at grinding stellite with a general purpose CBN wheel result in the material being pushed along the surface, rather than cut away. This causes large burrs to form during the grinding process, and reveals an uneven surface finish.

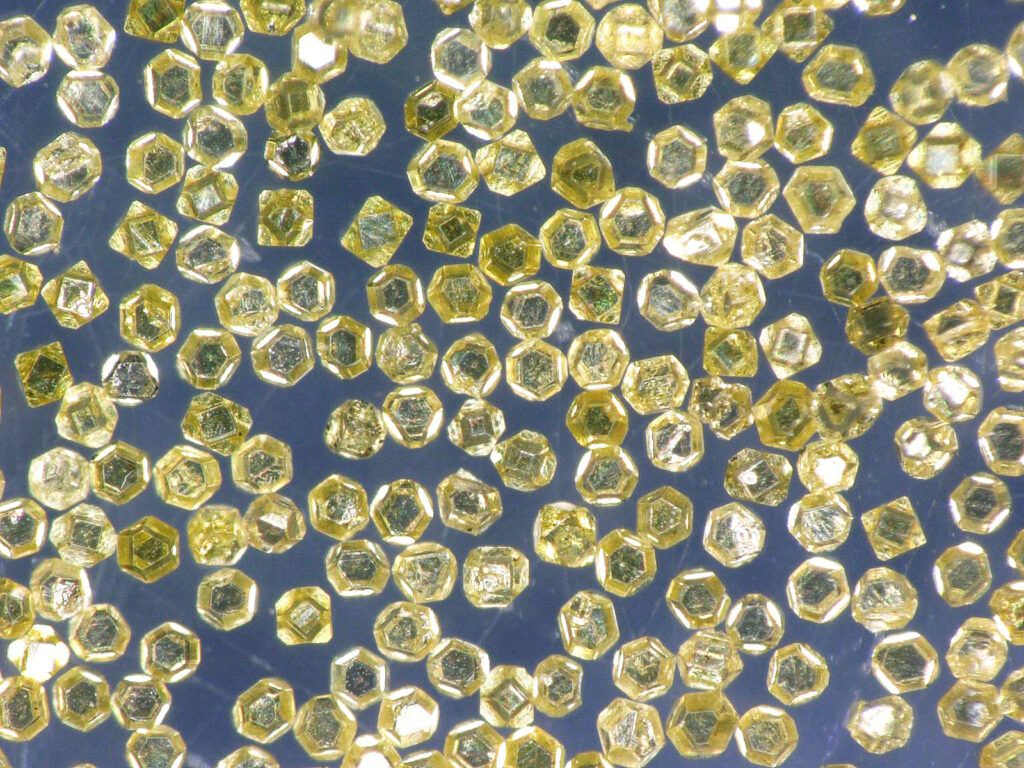

Many wheel consumers will already have a CBN wheel in their arsenal, but as previously discussed, not every CBN wheel is designed to cut stellite. If you’re a return reader you may recall the many times we have discussed the importance of considering what material is to be cut when choosing grit size, shape and bond structure of your grinding wheel. General purpose CBN wheels are designed to grind hardened carbon steels using a blockier shaped grit. In contrast to carbon steel, stellite is a much more ductile material. Blockier CBN particles are able to easily shear off bits of hardened steel, but fail to completely remove stellite from the grinding surface, pushing it along creating large burrs.

To remedy this, Eagle incorporates a specifically formulated CBN particle designed to cut stellite and minimize the burrs generated during the grinding process. Paired with the more aggressive resin bond structure, these sharper CBN particles are able to cut through stellite, maintaining a clean cutting surface ready for use on other viable materials. John Coleman, one of Eagle’s application engineers, provides the perfect analogy:

“It is similar to the idea that squares are rectangles, but rectangles are not squares. Eagle’s CBN wheels are formulated to grind stellite while also being usable on steel. General purpose CBN wheels will only successfully grind ferrous materials.”

Need more answers? The engineers at Eagle are ready to assist if you need further stellite grinding advice. Eagle offers free consultations with no pressure involved!

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel

Grit Size & Impact on Performance: Engineer Interview