When it comes to grinding wheels, the bond system is just as important as the abrasive type. Of the multiple bond systems we offer, vitrified bonds are typically the least understood, however, they are attracting more attention thanks to their improved performance and lower cost.

What is a Vitrified Bond Wheel?

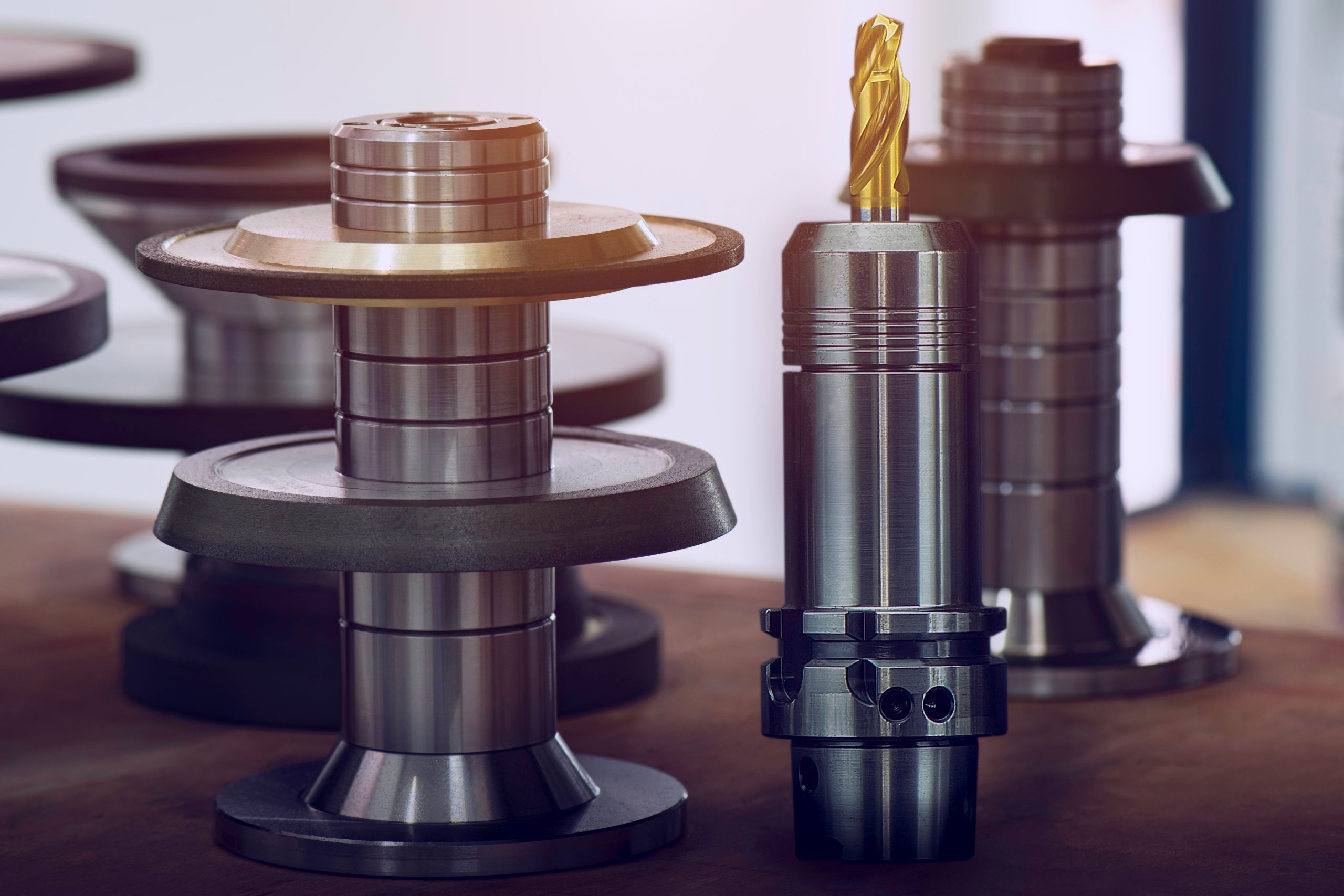

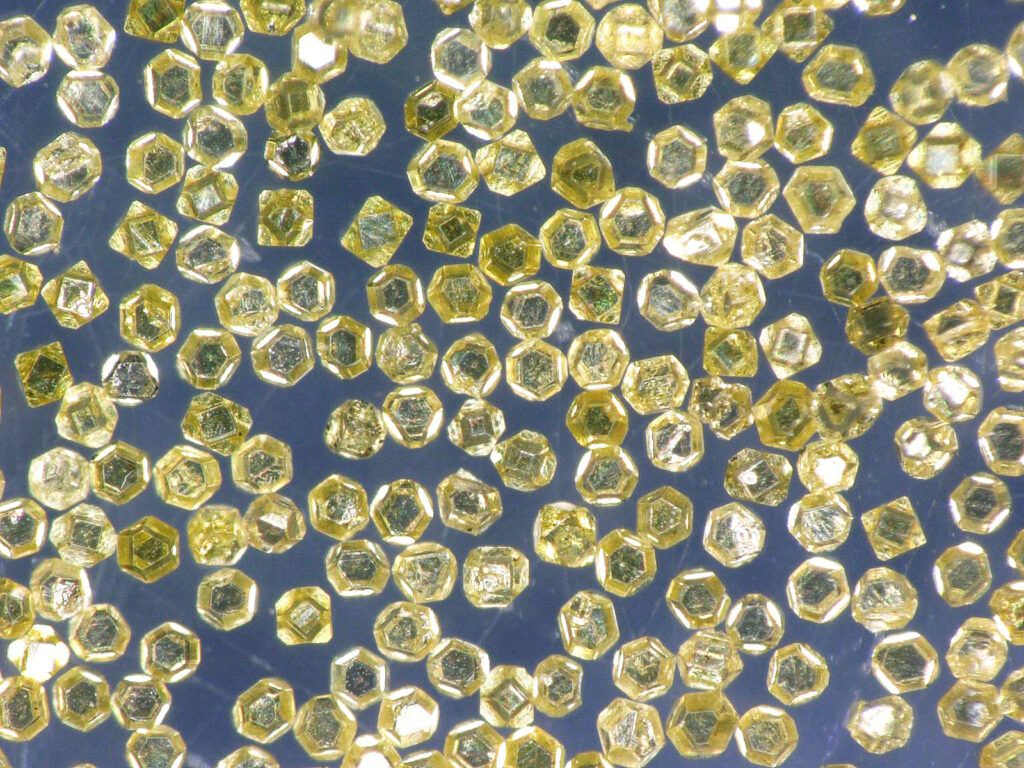

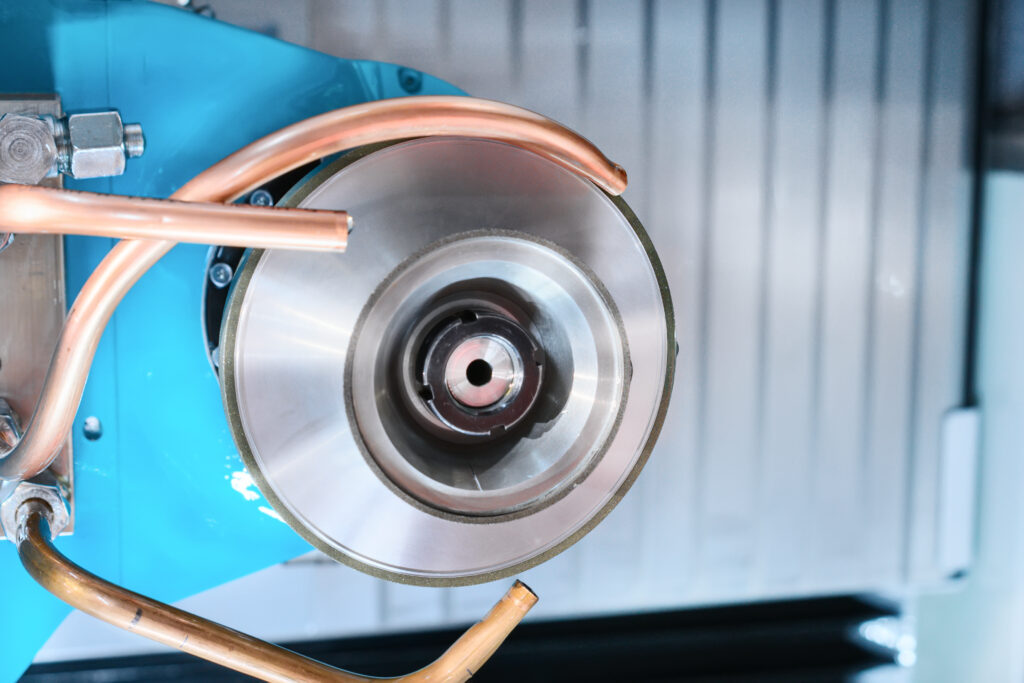

Vitrified bond grinding wheels contain a superabrasive (diamond or CBN) and either glass or ceramic particles. The mixture is pressed prior to firing in the kiln. The result is a glass-like structure that is extremely porous. The grit is held in a rigid matrix.

Plated wheels contain one bond layer, whereas vitrified bond wheels can have greater depth. The wheel is then able to be dressed multiple times. As it is grinding, the bond fractures and releases the worn grit to expose the fresh edges, making the wear rate very low. Complex profiles can also be achieved by putting a form into the wheel (although this does not complicate dressing).

What are the benefits of Vitrified Bond Grinding Wheels

The most notable benefit is the open, porous structure which allows the grit to stand out from the surface of the bond. This creates a wheel that is “free cutting”, providing adequate space for chip clearance.

Having a free cutting wheel increases material removal from the workpiece, reduces wear, and lessens dressing frequency. It also allows coolant to be carried through to the grinding zone and lowers overall forces, therefore reducing heat and possible workpiece damage.

Greater control is maintained over the final size when working at lower temperatures. The rigid nature of the wheel also contributes to precision. With low thermal growth and minimal wheel deflection, high tolerances can be maintained throughout the production run.

APPLICATIONS

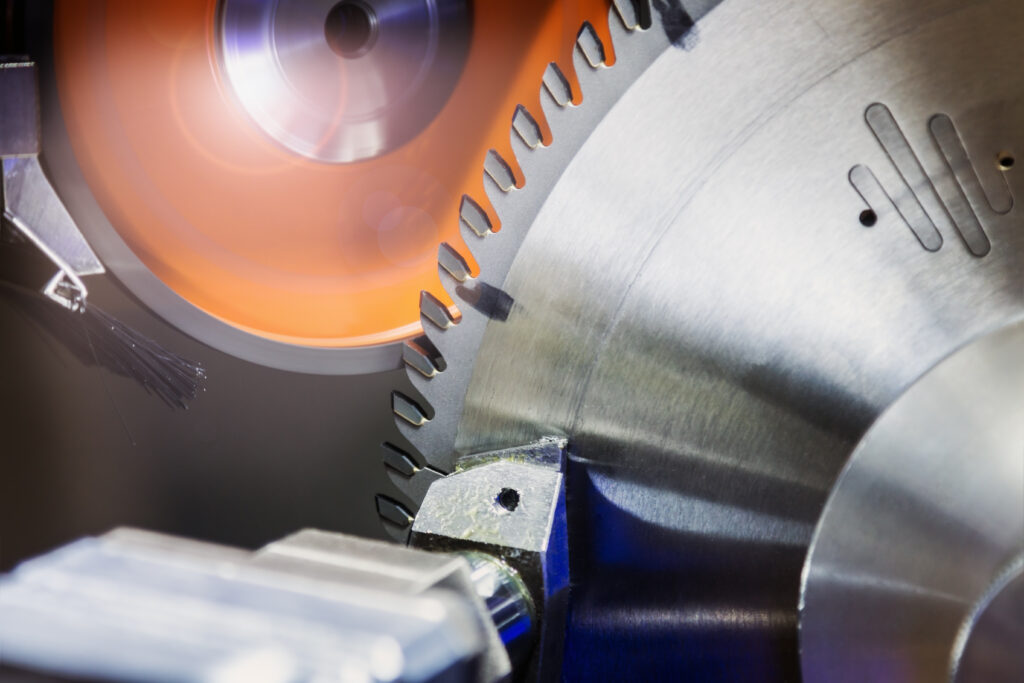

Vitrified bond wheels are ideal for high-volume applications. Their free-cutting ability combined with low wear rates and ease of dressing mean high stock removal rates and greater intervals between wheel changes.

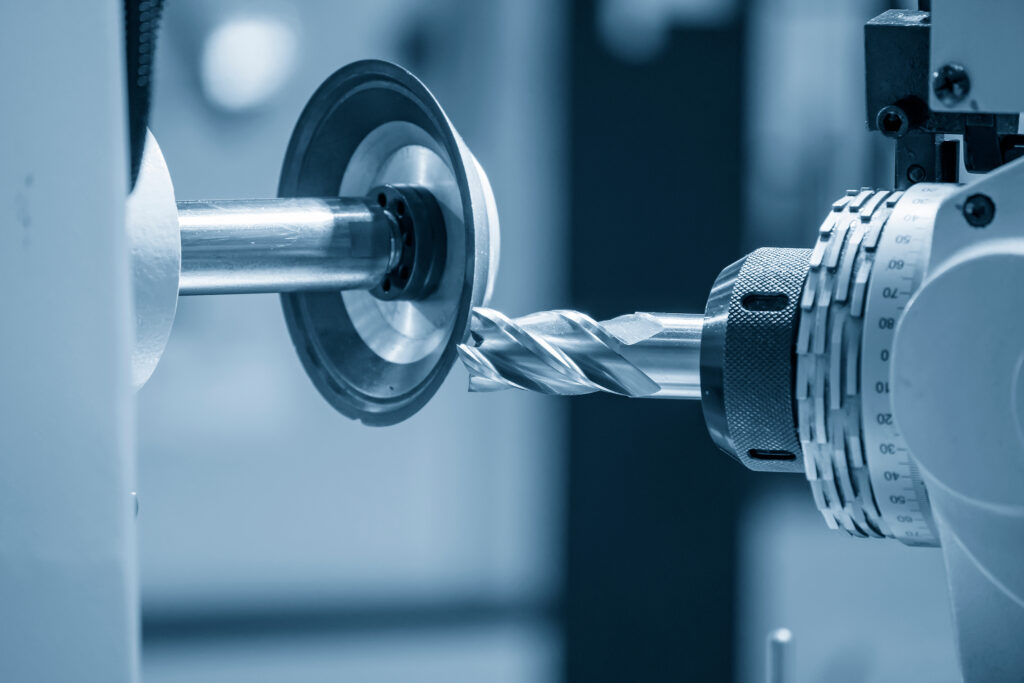

When grinding ferrous materials, cubic boron nitride (CBN) wheels are preferred. Some common applications include camshafts and tool steel. Diamond, on the other hand, is preferred for ceramics, carbides, and other non-ferrous materials.

A HIGH-VOLUME WHEEL

Of the multiple bond types we offer, a vitrified wheel is best suited for high-volume and extended run applications. The rigid, porous structure delivers high stock removal rates, extended wheel life and ultimately lowers your manufacturing costs.

Eagle is here to answer any questions you may have. No pressure- just answers. Get in touch with us today!

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel