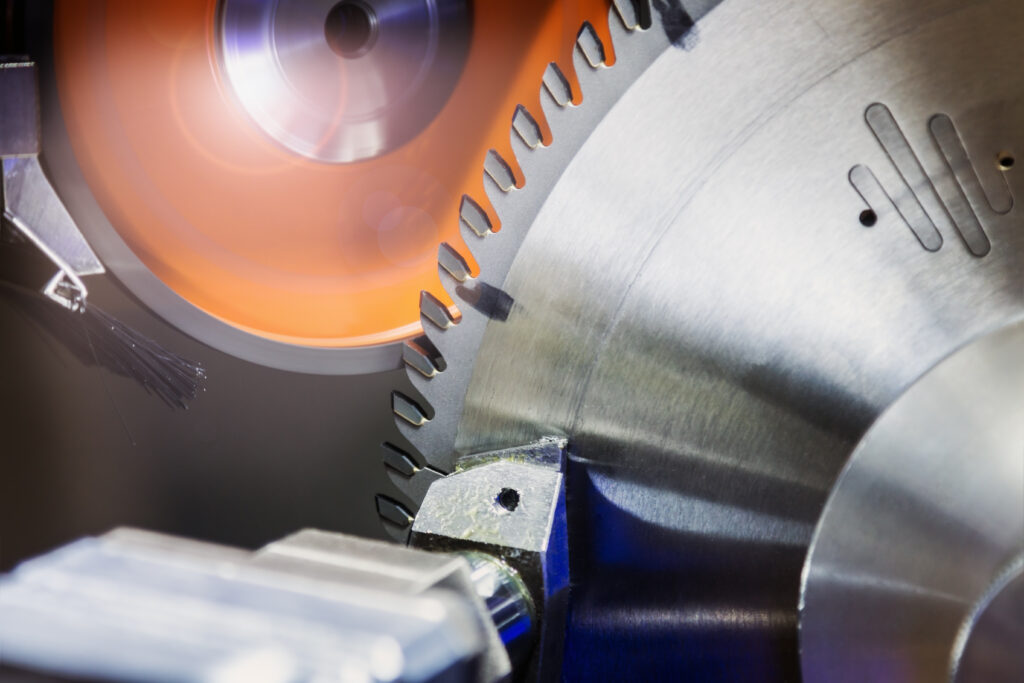

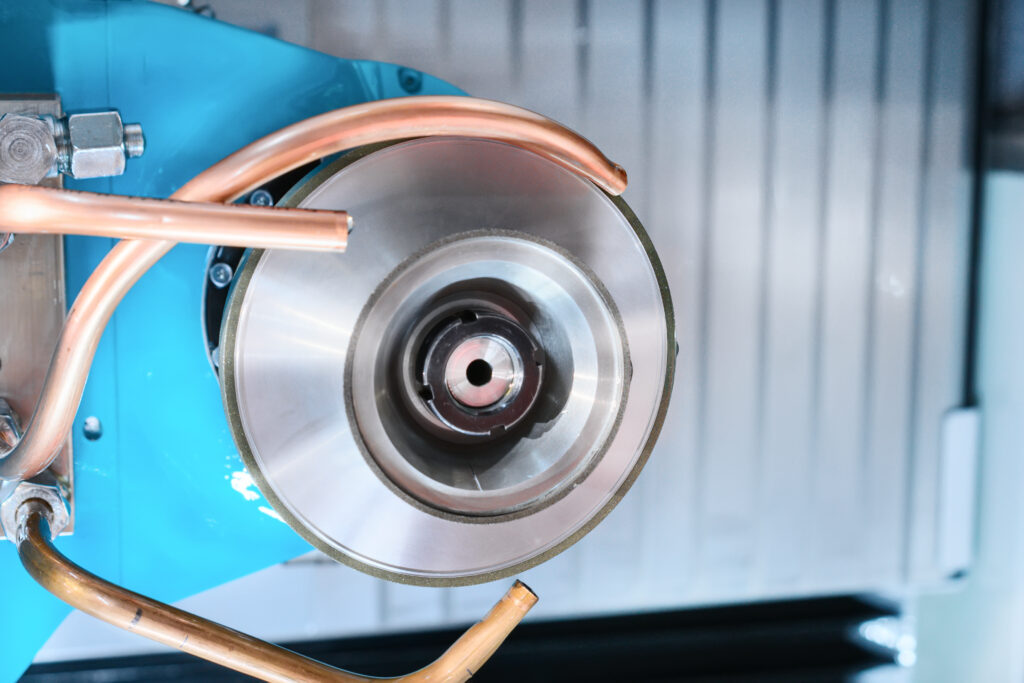

If you’re in the market for a grinding wheel, you will quickly find that there are quite a lot of options. One of the most commonly used superabrasive wheels in industry, the diamond grinding wheel (a grinding wheel containing diamond particles) is utilized across an exceedingly wide range of industries including aerospace, automotive, tooling and much more. But what exactly makes the diamond wheel such a popular option among so many manufacturers? Let’s dive into the specifics of diamond wheels, their uses, and variations with Eagle’s own Keith Hendrix.

Diamond Wheels Q&A

As an Application Engineer at Eagle Superabrasives Inc., Keith has ample experience providing customers with the perfect grinding wheel solution for their unique application.

E- “Keith, can you tell me about some of the industries that use diamond grinding wheels?”

K- “There are a ton of applications for diamond wheels. I’ve seen them used in aerospace, automotive, tooling, anything involving carbide.”

This got the wheels turning for me, pun intended. How can diamond wheels be such a universal choice? Surely there isn’t a one-size-fits all wheel?

E- “So, are all diamond wheels created equal? How can they be in practice in so many different applications?”

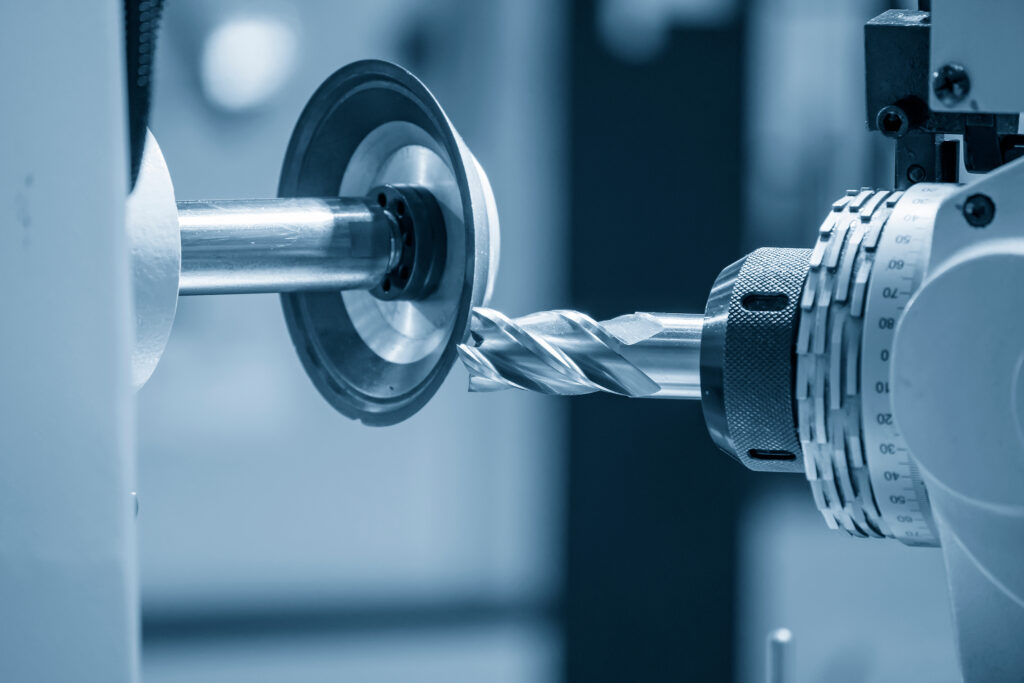

K- “Well, there are several different kinds of diamond wheels. The wheel shape, abrasive, bond, and core material can change depending on the application. A softer bond will give you a better cut, but it comes with a shorter lifespan. A harder bond will last a lot longer, but may not have the same performance.”

So, diamond wheels are great for a plethora of applications, but when is a diamond wheel not recommended?

E- “Are there any applications where you wouldn’t suggest a diamond wheel?”

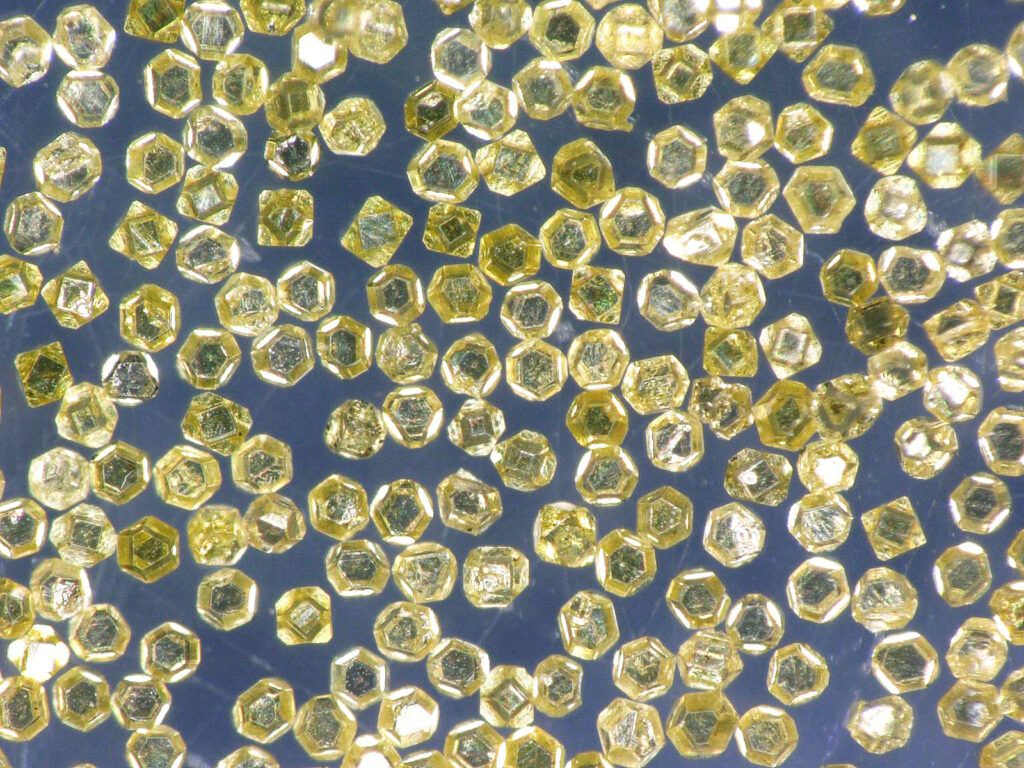

K- “Diamond is the hardest material on earth, and diamond abrasive wheels are known as superabrasives. They really don’t do well on softer metals like stainless steel. Regardless of the bond, I wouldn’t suggest a diamond abrasive to anyone looking to grind soft materials less than 45 Rockwell C. CBN (another superabrasive) can be used for softer metal, but will need truing more often. If you grind a soft material on a diamond wheel, the material will gum up the abrasive.”

With so many different diamond wheels on the market I started to wonder, why Eagle? What about their wheels makes them the best choice for finding a grinding solution?

E- “There are, no doubt, a lot of diamond wheel variations on the market. Why should customers choose yours over the competitor options?”

K- “The commitment to finding the perfect balance for your application is what truly sets our wheels apart from the competitor’s. Sometimes it takes some trial and error to find the right bond for your application, and at Eagle we’re willing to work with our consumers until we get it just right.”

E- “So what does a search for the perfect grinding wheel look like with you?”

K– “The best thing a customer can do is call in with as much information as they can find about their manufacturing process, materials, wheel speed, machine in use, etc.. As an Application Engineer, I can walk you through the products we would suggest to fit your needs. However, our customer service doesn’t stop until your process is running smoothly. The biggest thing that sets Eagle apart is that we will continue to serve you until you’ve got the perfect grind.”

“To effectively sell a product, you have to believe in it. And I truly believe in our products.”

Keith’s final quote spoke volumes to his confidence in Eagle’s ability to serve their customers with quality products.

“To effectively sell a product, you have to believe in it. And I truly believe in our products.”

Diamond Wheel Options

After speaking with Keith, I wanted to dig a little deeper into the technical side of diamond wheels.

His reference of diamond abrasive as a “superabrasive” is an industry standard term referring to the contrast between diamond abrasive and standard abrasive wheels which use aluminum oxide and silicon carbide. It is well known that diamond wheels offer superior strength and durability over conventional grit wheels, especially when grinding carbide, ceramics, or glass.

Although Keith and I discussed differing lifespan within the diamond wheel realm, when compared to standard wheels, diamond wheels have an exceedingly longer lifespan due to their hardness. Their thermal conductivity also plays a large role in their long lifespan, with heat capacity ranging over 2000% better than the standard wheel.

But what about the different kinds of bonds and diamond grit shapes? Diamond wheels can be manufactured using metal, hybrid, vitrified, resin bonds and more. Within those bond options, there are further opportunities for fine tuning. For example, if you require a resin bonded wheel we will have the ability to choose between many different resin formulations. The diamond particle also comes in many different forms with different coatings. Wheels are available in varying shapes and sizes based upon the material being ground and the machine the wheel is used on.

contáctenos para una cotización gratis

o llámenos al 33 31255419 – 33 36315374

Support When You Need it

Now that we have ventured in depth on the many concoctions available within the category of diamond wheels, it is easy to become overwhelmed with all of the options. I can now understand just how important Keith’s praises of Eagle’s customer service were. With an impossibly large range of diamond wheel combinations, having an Application Engineer like Keith to walk me through the options would be essential. I can say with confidence, if you’re in the market for a grinding wheel, Eagle’s team is ready to provide expert advice and quality customer service to ensure your abrasive does its job right.

Whether you are looking for general guidance or are ready to get a quote, we are dedicated to helping you find the right solution – and if we can’t provide the exact wheel you need, we will let you know. Eagle values communication and we will never lead you on. We hope you’ll explore the ways our team can help your business realize its potential.

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel