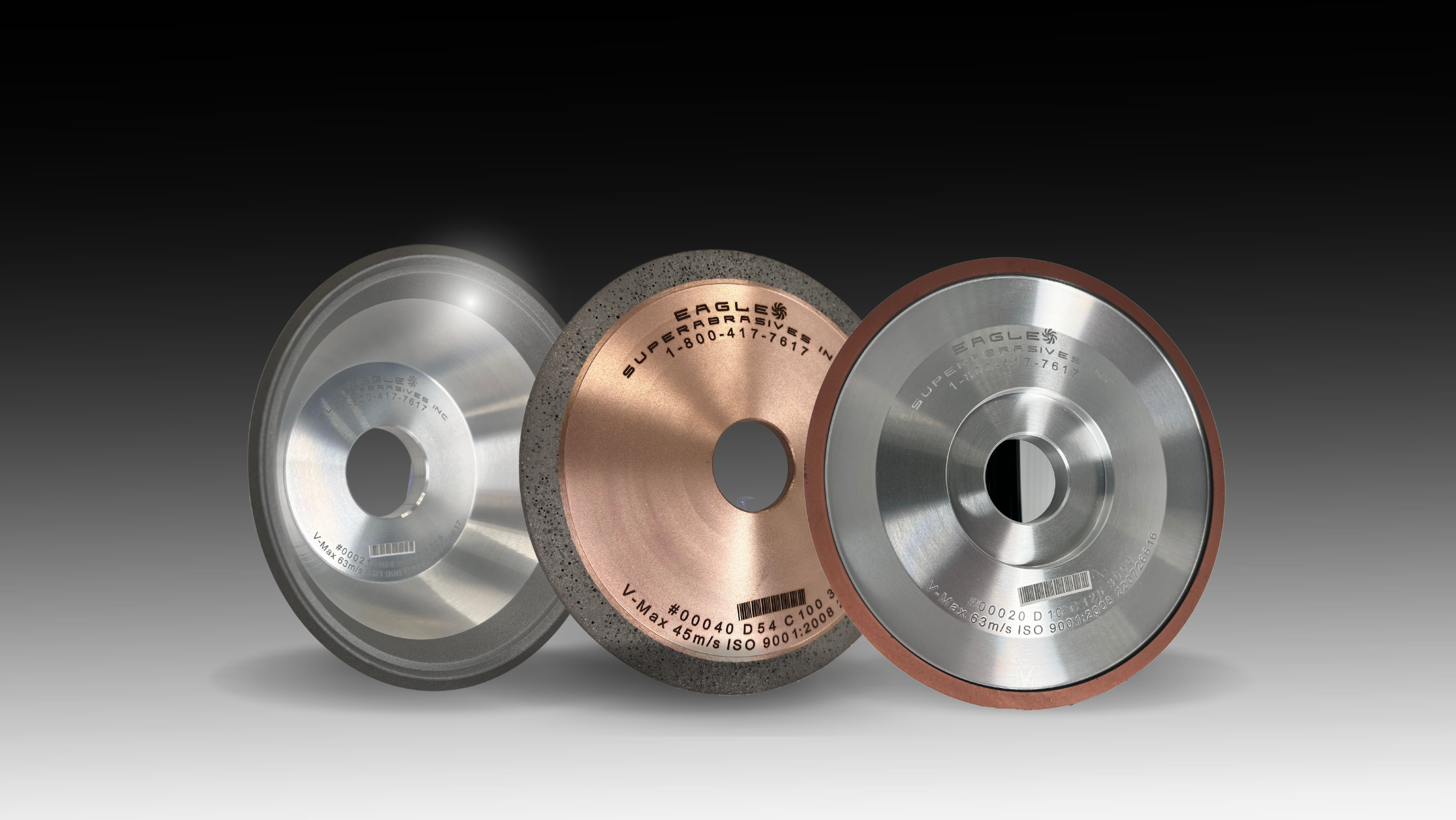

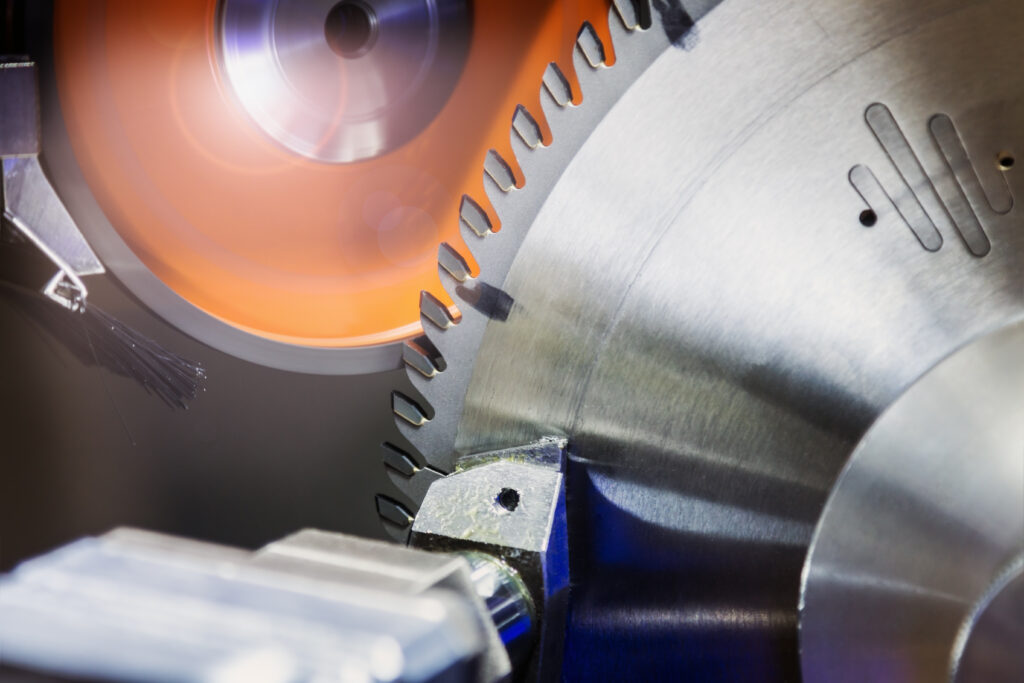

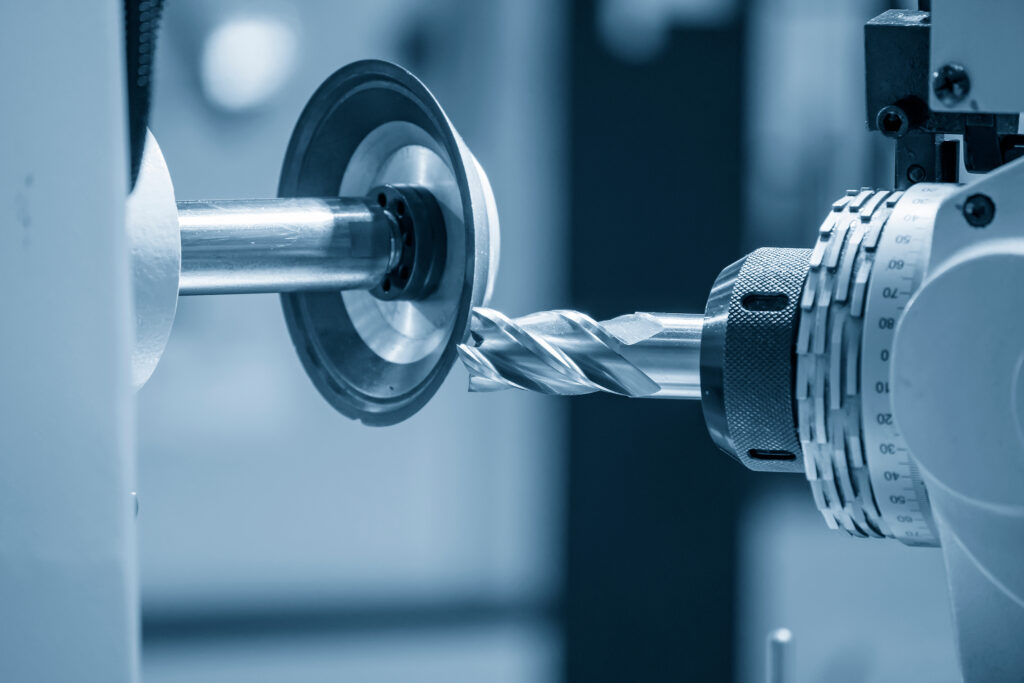

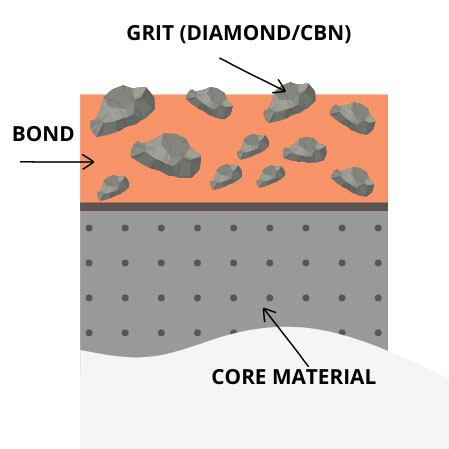

A grinding wheel is an abrasive cutting tool used in machinery operations across various industries to cut, slice, or refine extremely hard materials. Comprised of a bond and superabrasive, grinding wheels contain thousands of grain parts with multiple cutting edges to seamlessly shape a workpiece.

A grinding wheel with the proper bond, abrasive, and core material formulation for the specific application will also sharpen itself on an ongoing basis. This intentional process extends the life of the wheel, positively impacting the productivity and profitability of operational machinery.

However, selecting the optimal grinding wheel for your application requires considerations that may impact the long-term success of your operations. Here’s what you need to know and consider as you search for a wheel for a specific project or when looking for a new vendor for your large-scale business.

What are the different types of grinding wheels?

Grinding wheels come in a variety of shapes and sizes to accommodate unique grinding applications. Each type will have a distinct abrasive grain to remove material from the workpiece. Abrasive grains and bond types can be combined to create the perfect grinding wheel for the specific material. Selecting the right wheel type for a given application enables you to complete your work and obtain efficient stock removal and precision.

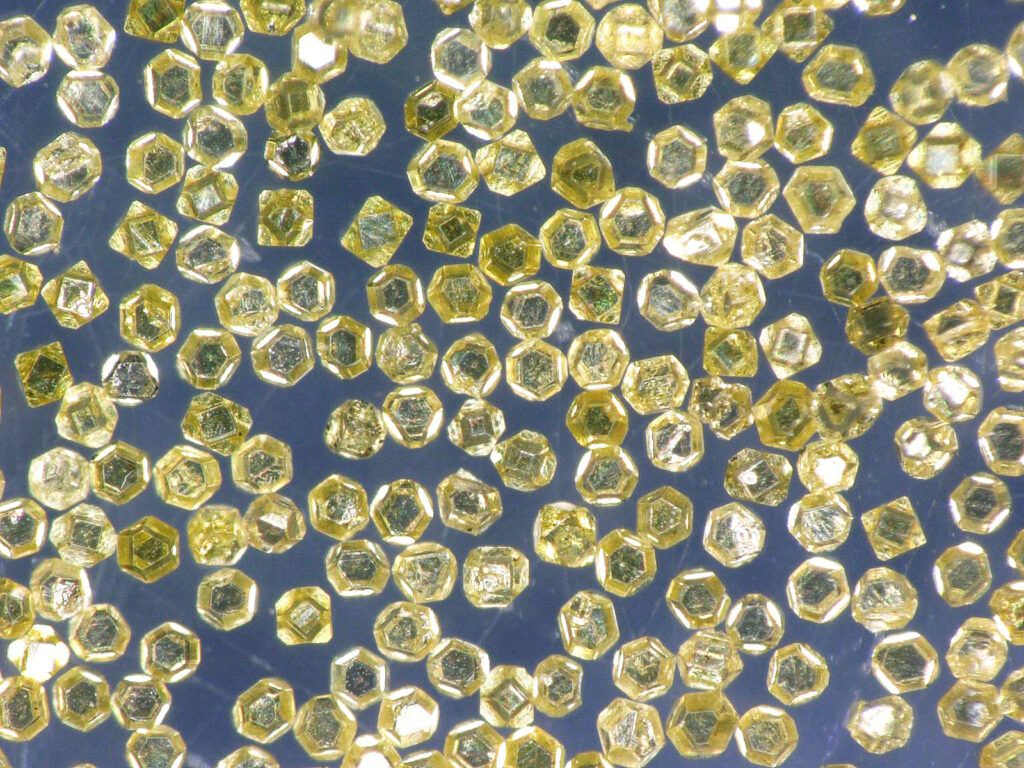

Diamond Grinding Wheels

Diamond, the hardest naturally occurring element on the planet, contributes to a longer-lasting grinding wheel. This is especially true when compared to applying conventional abrasive wheels to substances such as steel or carbide. Diamond wheels are used to grind high-hardness, non-ferrous materials. CBN wheels should be used on ferrous (iron-rich) materials with a hardness above 40HRC.

What are diamond wheels used for?

Diamond wheels are great for working with non-ferrous, difficult-to-grind materials (DTG) such as:

- Carbide-tipped cutting tools

- Glass

- Ceramics

Diamond wheels allow for high stock removal rates and precision without burning the surface or cracking the workpiece. Our diamond wheels are made with synthetic poly-crystalline or mono-crystalline diamonds, offering the hardness and thermal conductivity equal to (or higher than) that of natural diamonds.

While the abrasive material and coating type are essential to manufacturing the right diamond grinding wheel for the job, you should also prioritize selecting the proper bond for your intended application.

Our proven bond systems lock in carefully selected diamond abrasive powders to ensure there is almost zero diamond pull-out. We utilize a careful engineering process that produces a long-lasting, sharp, and durable grinding wheel.

CBN Grinding Wheels

CBN stands for cubic boron nitride. As a superabrasive, CBN outperforms diamond when used for ferrous grinding operations. While diamond begins to lose a significant amount of hardness at around 700 degrees, CBN remains unchanged at over 1,000 degrees.

What are CBN grinding wheels used for?

CBN grinding wheels are the top choice for iron-rich hard materials such as bearing, hardened steel, and nickel-based alloys. Their unique features provide a smooth, consistent finish.

CBN wheels can be used in:

- Tool and surgical knife cutting

- Compressor parts

- Fuel injectors

- Beyond these applications, many use CBN wheels to cut different HSS metals. These include wooden tools, cutters, bits, and blades. Our wheels retain CBN particles longer because of our unique bond system that extends wheel life. As a result, the wheel provides maximum durability, cuts cool and avoids tool burning.

CDX Grinding Wheels

While not as common or adaptable as CBN or diamond wheels, CDX wheels deserve to be highlighted. Specially formulated to grind tungsten carbide and steel simultaneously, CDX wheels contain the mixing of CBN and diamond powders required to grind dissimilar materials (C for CBN, D for Diamond, and X to signify the mixture).

Tools such as carbide-inlaid profiling knives, Bac-Pac systems, and special-tipped tools can be ground quickly while reducing wheel loading and thermal damage to the tool material.

How to choose a grinding wheel

Once you have determined the proper wheel type for your application, whether diamond, CBN, or CDX, it’s time to consider the formulation of the wheel itself. Here are the key factors you should consider when deciding on product fit and investment.

Machine type

Before diving into wheel details, ensure you know your operating machine’s specs. Review these traits of your machine to gain a better understanding of which wheel type will work best for your application:

- Is it manually operated or automatic?

- Does the machine uses coolant (oil, water-soluble, etc.)?

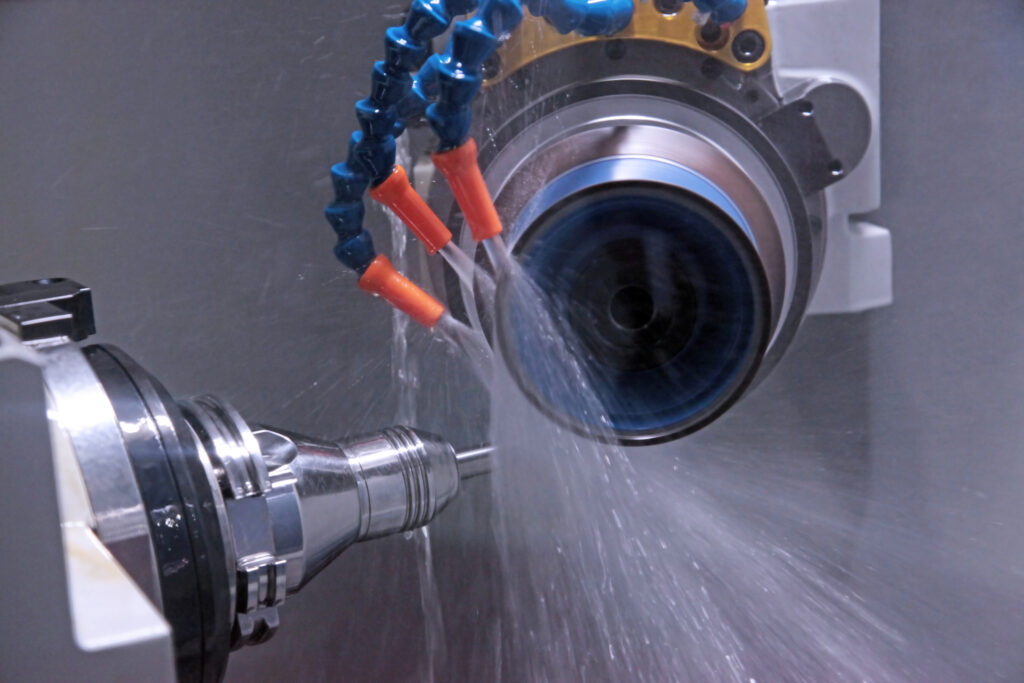

Coolant use

To expand on the point above: should you use coolant on your grinding wheel? Our recommendation is — yes. Although resin bond wheels may be used dry, coolant increases efficiency and greatly extends wheel life. The use of coolant (or lack thereof) also determines the wheel formulation that works best for your operation.

Abrasive grit size

The grit size used in your wheels is derived from mesh sizes, mesh acting as the standard way of grading power. Like sandpaper, larger particles remove material faster but leave a coarser finish. The finer the mesh is, the less material is removed at a time, and the smoother the overall finish.

Abrasive concentration and hardness

The concentration of the abrasive in the grinding wheel will determine its hardness. Hardness depends on the wheel’s grit type, the material being ground, the amount of stock to be removed, and more. It can vary depending on the project type and the producing company, as there is no industry standard. Hardness typically falls on an A-Z scale, A being the weakest bond and Z being the strongest.

Spindle speed

Wheel or spindle speed is determined by application. Lower speeds make the wheel act softer and coarser, while a higher speed range makes the wheel act harder and finer.

Grinding wheel shape & size

Grinding wheels are available in a wide range of wheel shapes and sizes to suit any machine or process. For example, diamond and CBN wheels can be as thin as 0.2mm and in excess of 30 inches. Whether you’re roughing or polishing, your workpiece material and desired result will affect the shape, size, and overall formulation of your grinding wheel. If you’re unsure of the proper size or shape requirements for your application, we recommend consulting with our experts to determine the best wheel specifications for your operation.

Grinding wheel bond types

In addition to abrasive type and shape, the importance of choosing the right bond type cannot be overstated. The bond of a grinding wheel holds the abrasive grains in the wheel while they cut or grind the material. At the same time, the bond continuously releases the grains as it wears down, and the sharp edges of the abrasive are removed. The bond controls much of the grinding process and the end result.

For example, if you have a bond that’s too hard for the target material, it will erode the superabrasive part of the wheel. To maintain wheel longevity and attain desired results, ensure that the bond and the superabrasive wear away at similar rates. These rates depend on the bond type, temperature, pressure, and other application-specific factors.

Several different types of bonds can be formulated for wheels:

Resin bond grinding wheel

Resin is the most commonly used bond type. Resin bonds are made of various resins combined with fillers. Eagle offers two types of resin bond wheels: phenolic and polyimide resins. The phenolic resin bond can be used for wet or dry grinding, off-hand grinding, centerless grinding, and general tool grinding. Depending on the demands of the application, however, polyimide resin bond CBN wheels are a harder resin that can offer superior performance over phenolic resin bonds. The polyimide bond drastically increases the wheel’s ability to hold form and has a higher temperature tolerance due to the thermal properties of the resin.

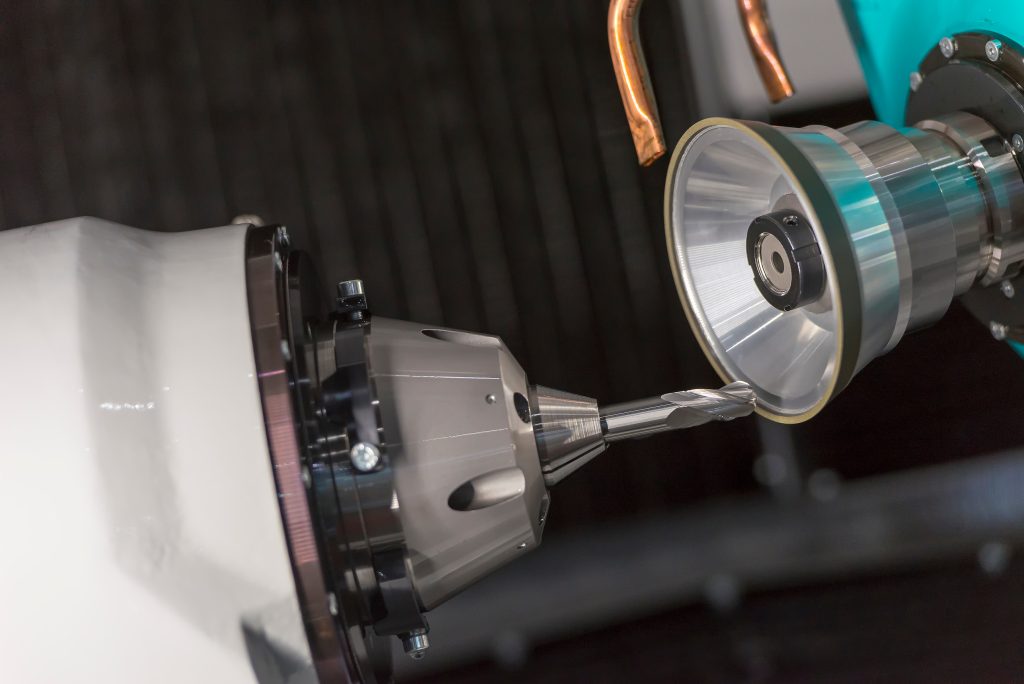

Hybrid bond grinding wheel

Hybrid bonds have become the industry standard bond for the manufacturing of end mills and cutting tools. These bonds reduce cycle times and remove material 10x faster than resin bonds. Plus, they offer higher thermal stability without causing damage to the tool and lower spindle loads.

Electroplated grinding wheel

With our multilayer electroplated bond system, abrasive grains are attached to wheel cores with a very strong nickel coating that chemically and physically attaches the diamond or CBN to the wheel body. As a result, electroplated diamond and CBN grinding wheels can cut and grind a variety of hard materials efficiently. Electroplated bonds hold their profile for the life of the wheel, making them perfect for intricate profile grinding.

Metal bond grinding wheels

Metal bond grinding wheels are ideal for grinding glass, certain composites, and some metals. Metal bonds are built for endurance and form-holding performance. Using a metal bond helps to enhance the life and form holding of the wheel. By applying CBN or diamond powders to the metal bond, you’ll enjoy a product that holds its shape longer than any other bond system during use.

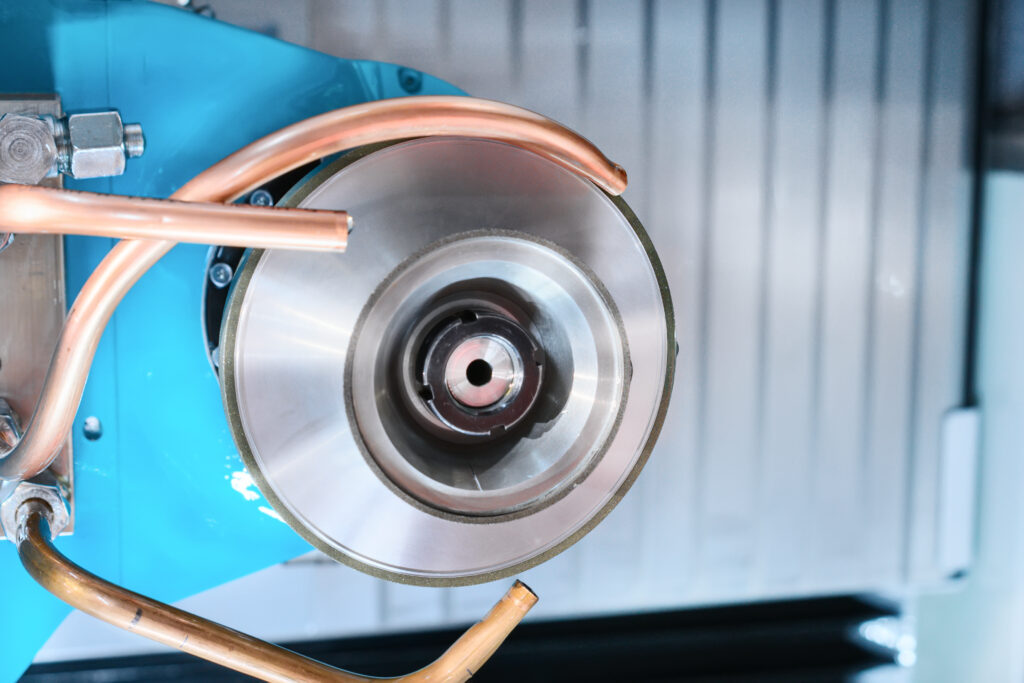

Vitrified bond grinding wheel

Vitrified bonds allow the grinding wheel to be very rigid, strong and porous. These characteristics each provide many benefits to the wheel. Having a rigid wheel allows for strong cutting performance and increased grinding speed. Another added benefit of the vitrified bond is its porous character. The porosity of the wheel allows coolant to penetrate between the workpiece and the wheel to effectively remove heat from the point of contact. Any reduction in heat generated while grinding will extend the life of the wheel.

Polyimide bond grinding wheel

Polyimide is a resin made to withstand high temperatures. Though manufactured in the same way as a standard resin in many ways, the pressing temperature is about three times that of resin bond, offering pressing forces up to five times more. Eagle’s polyimide resin bond grinding wheels offer maximum grinding performance and excellent holding power, making them the bond of choice for CNC operations. Polyimide bonds also offer a lower power requirement. This results in the ability to achieve higher material removal rates.

Vacuum-brazed diamond grinding wheel

Vacuum-brazed wheels contain a single layer of super abrasive grit that is bonded to the core with a proprietary alloy mixture that is melted around the abrasive grit and cooled to lock the abrasive grit in place. An extremely blocky diamond grit is used because vacuum brazed wheels are typically used in processes that require high durability.

Rubber bond grinding wheel

Rubber-bonded wheels are extremely durable and strong. The main uses of rubber bond wheels are as thin cut-off wheels and driving wheels in centerless grinding machines. They are used also when very fine finishes are required on bearing surfaces. Rubber bond can provide a superior finish, are cost-effective and have the ability to grind and polish composite in a single pass.

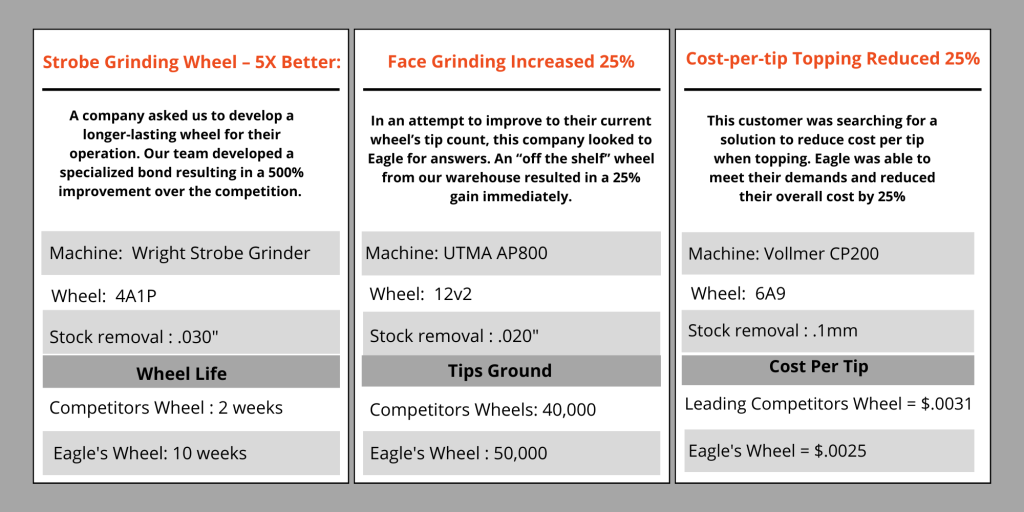

The importance of selecting the right grinding wheel

A custom grinding wheel formulated with the correct bond, abrasive, and core for your specific application will offer the best results. Here’s how our customized, grinding wheels perform against the competition:

Many technical factors must be considered when choosing the right grinding wheel. Using the wrong wheel can negatively impact your production and final results. With these factors in mind, having dedicated support from an engineer is invaluable. Most grinding wheel suppliers tend to locate a requested wheel in the catalog or inventory and ship it over if available, but that doesn’t mean that it will be the most efficient wheel for your application.

What should you look for in a grinding wheel supplier?

A consultative approach

Look for experienced engineers who are committed to their customers’ success and will guide you through the process. Whether you know exactly what you need or are starting from scratch, the right supplier will be eager to adjust their product recommendations as your needs and operations evolve.

Timeline considerations

Great suppliers are equally prepared to meet urgent requests as best they can. They also deeply understand the various applications that may require highly-customized solutions and those that do not. No matter your needs, the right partner will determine the best solution based on your timeline.

A focus on quality

When it comes to grinding wheel suppliers, quality comes in two forms, product and support. Here are the signs to look for in a supplier that values quality in both areas:

- A pressure-free conversation with an engineer who has the knowledge to ask the right questions.

- Engineers that will ensure the grinding wheel meets (or exceeds) your standards.

- A team that speaks your language, no matter how technical or nuanced, and understands your desire to balance technical needs with the speed of delivery.

- Transparent communication that enables you to meet operational requirements without overly sales-focused conversations.

- Competitive pricing without sacrificing product quality.

Whether you are looking for general guidance or are ready to get a quote, we are dedicated to helping you find the right solution – and if we can’t provide the exact wheel you need, we will let you know. Eagle values communication and we will never lead you on. We hope you’ll explore the ways our team can help your business realize its potential.

Hard vs Soft Grinding Wheels

Resin Bond Grinding Wheels: Formulations & Uses

Stellite Grinding: 101

How to Find an Expert Grinding Wheel Supplier

Grit Size: Impact on the Grinding Process

Purchasing diamond wheels without the pressure

Electroplated Grinding Wheels 101

Improving the Performance of a CBN Grinding Wheel