The electroplated diamond wheel is a superabrasive wheel that is known for maintaining its shape.

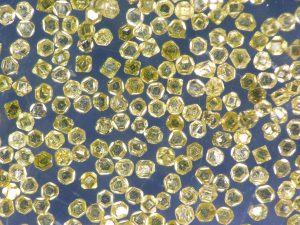

The electroplated wheel has a single layer of abrasive grains attached to the wheel core by very strong Nickel matrix coating that chemically and physically attaches the Diamond to the wheel core.

Applications as simple as chainsaws and bandsaw sharpening to more complex special shaped wheels for intricate geometries.

Hard resin bond wheels can not hold their form longer than the fast-cutting capability of the Electroplated bond wheel.

Metal bond wheels can hold their form longer than resin bond wheels, but unless metal bonds are grinding glass or other very abrasive materials the metal wheel bonding will not break down quickly enough.

The only guaranteed option for wheel shape retention is electroplated bond wheel.

Contact one of our Application Engineers and we can explore what option is best for your applications.