Compuestos

Corrosion, Heat & Impact Resistant

Diamond grinding wheels are ideal for cutting, grinding and milling hard-to-shape materials, including carbon fiber, fiberglass and fiber-reinforced plastics (FRP), all of which are prevalent in manufacturing composite products. Using traditional tools (drills and mills made from hardened tool steel or carbide), can result in fiber pullout, de-lamination, heat damage, chipping, and greatly enhanced wear to the tools. As conventional tools dull, the product’s surface integrity is often damaged, and the dimensional accuracy and component quality become unsatisfactory. How do you fix this issue?

Unlike these types of tools, Eagle’s diamond wheels are made to cut hard, abrasive and brittle materials and minimize the issues that make conventional tooling ineffective. We offer multiple options to fit your specific needs and achieve your desired results.

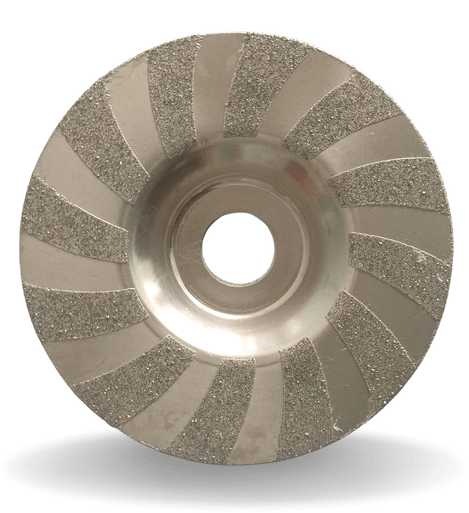

Perma-Plate Wheels

Electroplated wheel peeling at the core? With Eagle Superabrasives’ Perma-Plate Guarantee, there is no need to struggle with peeling wheels any longer!

Our electroplated wheels are made with our multi-layer system, in which a very durable nickel coating chemically attaches the diamond or CBN abrasive grains to the core and keeps them there. In addition, Eagle’s Perma-Plate wheels utilize a secondary Nickel Matrix Encapsulation Layer, creating even tighter adhesion of the abrasive particles to the wheel cores.