Metal

Metal bond grinding wheels work best in wet grinding applications. Giving the wheel long life due to lower grinding temperatures. Metal bond grinding wheels maintain exceptional hardness and grit retention rates. Metal bonds allow for precise cuts that go uninterrupted, needing no dressing change and less wheel changes. For you, this results greater yield and more profit for your investment.

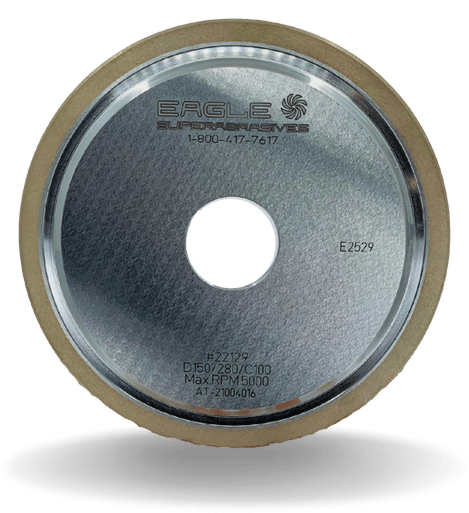

Metal Bond Diamond & CBN Wheels

When the heat is on in high demand grinding operations, metal bonded diamond and CBN wheels are the most durable and consistent abrasive solution. Exemplifying long tool life and low maintenance, the metal bonds in our MultiTec wheels are ideal for their extreme abrasion resistance.

Metal bond grinding wheels are ideal for grinding glass, certain composites, and some metals. Metal bonds are built for endurance and form-holding performance. Using a metal bond helps to enhance life and form holding of the wheel. By applying CBN or diamond powders to the metal bond, you’ll enjoy a product that holds its shape longer than any other bond system during use. Metal bond grinding wheels hold the superabrasive grain so strongly, that they last longer than any other bond type.

MultiTec Solution

The primary qualities of metal bonded wheels are endurance and performance. Selecting a metal bonded wheel is most important when used for operations involving form and plunge grinding, as well as grinding single-edged tools because of the exceptional abrasion, impact and wear resistance, resulting in maximum productivity per project.

NUESTRO COMPROMISO

Trabajando con Eagle, puede esperar discutir su proyecto con uno de nuestros ingenieros de aplicaciones altamente cualificados con sede en EE. UU. Juntos, ayudarán a identificar y proporcionar la solución de Afilado que mejor se adapte a sus necesidades y objetivos únicos. Nuestras capacidades de fabricación son insuperables en la industria.