Aspirate

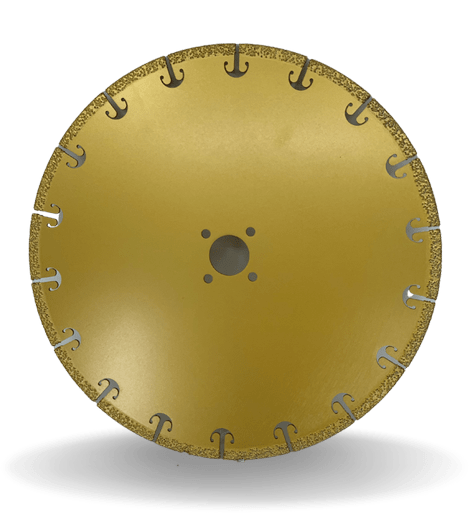

Our vacuum brazed diamond wheels are used for grinding, stock removal, and beveling in a wide variety of industries like metal processing, automotive, aerospace, ceramics, and composites.

What is a vacuum-brazed wheel?

Vacuum-brazed wheels contain a single layer of super abrasive grit that is bonded to the core with a proprietary alloy mixture that is melted around the abrasive grit and cooled to lock the abrasive grit in place. An extremely blocky diamond grit is used because vacuum brazed wheels are typically used in processes that require high durability.

Grit sizes range from D20/30 to D80, allowing for a large portion of the grit to be exposed. This allows for extremely aggressive grinding.

Additional Benefits

- High efficiency. the efficiency is improved by 30% for grinding cast steel surface, compared to conventional resin bond wheel.

- Up to 20 times longer life time than resin bond tools.

- A single layer of fully exposed diamond fused with nickel at high temperatures for sharp cutting power.

- Wheels never needs dressing.

- Vacuum-brazed wheels can cut 30% more efficient than regular resin bond wheels.

- Up to 20 times longer wheel life than conventional grinding methods.

NUESTRO COMPROMISO

Trabajando con Eagle, puede esperar discutir su proyecto con uno de nuestros ingenieros de aplicaciones altamente cualificados con sede en EE. UU. Juntos, ayudarán a identificar y proporcionar la solución de Afilado que mejor se adapte a sus necesidades y objetivos únicos. Nuestras capacidades de fabricación son insuperables en la industria.