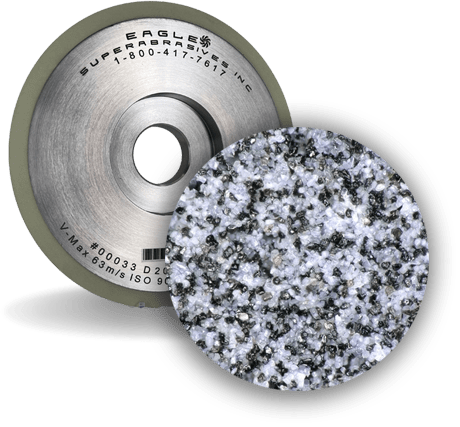

Vitrificado

Eagle manufactures our CBN and diamond wheels with vitrified bonds. Vitrified bonds allow the wheel to be very rigid, strong and porous. These characteristics each provide many benefits to the wheel. Having a rigid wheel allows for a strong cutting performance and increased grinding speed. Another added benefit of the vitrified bond is its porous character. The porosity of the wheel allows coolant to penetrate between the work piece and the wheel to effectively remove heat from the point of contact, and we all know that any reduction in heat generated while grinding will extend the life of the product.

Vitrified Bond Diamond & CBN Wheels

Vitrified bond wheels are typically used for grinding PCD and PCBN tools, ceramics and semi-conductors.

The combination of the vitrified bonds high thermal stability and our ability to adjust the bond structure allows for a more efficient coolant delivery to the grinding area of contact. These quality’s are key components in providing long wheel life.

Vitrified bond wheels are extremely aggressive and free cutting. They provide excellent tool life, require less downtime for dressing and truing, are cool-cutting and are suitable for “lights out” high production grinding.

Vitrified bond CBN wheels are typically selected for grinding Camshafts and Crankshafts, internal and external grinding of cylinders, etc.

Eagle’s VitTech ™ Wheels

The Eagle VitTEC™ wheels are designed for a multitude of grinding applications. Eagle VitTEC wheels are made in both Diamond and CBN, and are able to be custom-tailored to fit your specific material and grinding process. Eagle VitTEC wheels are made for applications ranging from PCD/PCBN tool production and grinding of ceramics and composites, to magnets, semiconductor components, to camshaft and crankshaft grinding.

Features

Benefits

While regular Vitrified bond wheels are cold compacted in two dimensions only, this often results in an uneven density throughout the segment which in turn results in poor and inconsistent wheel performance. Eagle’s VitTEC wheel segments and rings are Cold Isostatic Pressed (CIP). CIP process absolutely guarantees that the segments will have perfect density throughout the part as the abrasive section is pressed evenly from every single side, angle and radii.

NUESTRO COMPROMISO

Trabajando con Eagle, puede esperar discutir su proyecto con uno de nuestros ingenieros de aplicaciones altamente cualificados con sede en EE. UU. Juntos, ayudarán a identificar y proporcionar la solución de Afilado que mejor se adapte a sus necesidades y objetivos únicos. Nuestras capacidades de fabricación son insuperables en la industria.