Looking for a particular wheel?

Do you know the use for the wheel?

Do you have a picture to compare?

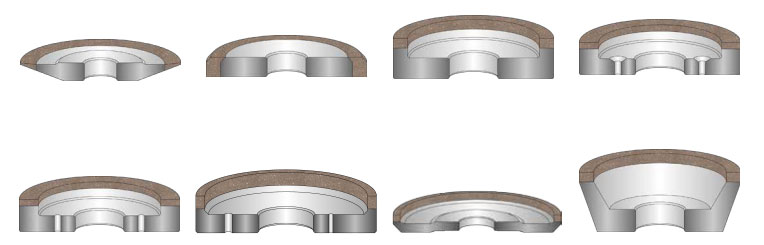

It can be confusing when trying to tell someone the type of grinding wheel you are looking for. Below are only a few applications and the wheel shapes you may use based on the machine you would be using. There are many wheel shapes that can be used for different grinding applications. Be sure to discuss with your application engineer all the different facets of your application so that they may direct you to the correct wheel shape for the job.

Cut-off, Grooving, Notching, Slicing, Dicing: 1A1R, 1E1, 14A1R

Facing, O.D. Relief Grinding, Tool & Cutter, Saw Grinding: 1A1, 4A2P, 4A2PTR, 11A2, 11V9, 12A2, 12V9, 15A2

Topping, Saw Grinding: 4A2, 6A2, 6A9, 12A2, 15A2

Knife Grinding: 1A1, 6A2, 1F1, 14A1R, 14F1R

Profile and Form Grinding: 1A1, 1EE1, 1F1R, 1V1, 3A1, 4BT9, 1Y1, 14A1R, 14F1R, 14V1R

Cold Saw Grinding: 14F1R Loroch, 14F1R Schmidt Tempo

Centerless Grinding: 1A1R (up to 27”)

I.D. Grinding: 1A1R (down to 1”), 1A1W, 1A8

Fluting and Gashing: 1A1, 1V1

Please note that we have pointed out the most common applications as there is an endless list of application.